The automotive industry is constantly evolving, and engine cooling systems play a crucial role in ensuring the optimal performance and durability of engines. When the third - generation Haval H6 2.0T model hit the market, it brought with it the 2.0GDIT engine, codenamed GW4N20. This engine is a technological marvel, boasting a torque of 325N·m and a thermal efficiency of 38%. It integrates numerous new technologies of Great Wall in traditional engines. To better understand its technological edge, we will compare its cooling system with that of the third - generation 2.0T EA888 engine from Volkswagen.

|  |

In 2012 and 2016, Volkswagen released the EA888 third - generation high - power GEN3 and low - power GEN3B engines, with further upgraded technology. The EA888 2.0T currently on the market is the subject of our comparison today.

EA888 Third - Generation 2.0T Engine Cooling System Analysis

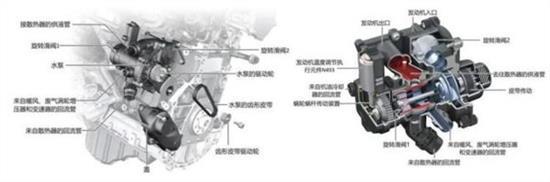

The third - generation Volkswagen EA888 cooling system features a combination of a belt - driven mechanical water pump and a cooling module. As shown in the figure below, the water pump is driven by a belt connected to the rear end of the intake - side balance shaft installed on the cylinder. This mechanical water pump has been a staple in automotive cooling systems for a long time. It operates based on the rotation of the engine's balance shaft, which in turn drives the pump's impeller. As the impeller rotates, it creates a centrifugal force that draws in coolant from the radiator and circulates it through the engine.

The rotary ball - valve - type electronically controlled cooling module based on MAP (Manifold Absolute Pressure) control is another key component. This module is designed to manage the water flow of various components such as the cylinder block, cylinder head, oil cooler, and warm - air system according to different engine working conditions. For example, when the engine is cold - starting, the module restricts the coolant flow to the radiator, allowing the engine to warm up more quickly. Once the engine reaches its optimal operating temperature, the module adjusts the coolant flow to ensure efficient heat dissipation. It does this by precisely controlling the opening and closing of the rotary ball valve, which directs the coolant to the necessary components. This system has been effective in achieving intelligent cooling system management, improving engine efficiency and reducing wear and tear.

GW4N20 2.0T Engine Cooling System Overview

The GW4N20 engine takes a different approach with its cooling system, opting for a more advanced configuration of an electronic water pump plus an electronic thermostat. The electronic water pump is a significant upgrade over traditional mechanical water pumps. Unlike mechanical water pumps that directly consume the engine's power, electronic water pumps are powered electrically. This means they do not place an additional load on the engine, thereby contributing to reduced fuel consumption.

The flow and opening of the electronic water pump can be flexibly controlled by the Engine Control Unit (ECU). The ECU receives data from various sensors in the engine, such as temperature sensors and pressure sensors. Based on this data, the ECU determines the optimal coolant flow rate required for the engine's current operating conditions. For instance, during high - load driving conditions when the engine generates more heat, the ECU can increase the speed of the electronic water pump to ensure sufficient coolant circulation. Conversely, when the engine is idling or under light loads, the ECU can reduce the pump speed, saving energy.

The electronic thermostat works in tandem with the electronic water pump. It precisely controls the temperature of the coolant by regulating the flow of coolant between the engine and the radiator. When the coolant temperature is low, the electronic thermostat closes, preventing coolant from flowing to the radiator and allowing the engine to warm up faster. Once the coolant reaches the optimal temperature, the thermostat opens, enabling the coolant to flow through the radiator for heat dissipation. This coordinated operation of the electronic water pump and electronic thermostat allows for more intelligent thermal management of the engine.

Performance Comparison between GW4N20 and EA888 Cooling Systems

Fuel Efficiency

In terms of fuel efficiency, the GW4N20's electronic water pump gives it an edge. Since the electronic water pump does not directly consume engine power, the engine can operate more efficiently, leading to potential fuel savings. In real - world tests, vehicles equipped with the GW4N20 engine have shown reduction in fuel consumption compared to vehicles with the EA888 third - generation 2.0T engine, especially during stop - and - go city driving conditions. This is because the electronic water pump can adjust its operation based on the actual cooling needs of the engine, unlike the belt - driven mechanical water pump in the EA888, which operates at a fixed speed relative to the engine's rotation.

Cooling Efficiency

The GW4N20's cooling system also demonstrates better cooling efficiency in certain scenarios. The ability of its electronic water pump and electronic thermostat to respond quickly to changes in engine temperature allows for more precise temperature control. For example, during rapid acceleration or high - speed driving, the GW4N20's cooling system can increase the coolant flow rate within seconds, effectively preventing the engine from overheating. In contrast, the EA888's mechanical water pump may take slightly longer to adjust the coolant flow, which could potentially lead to a temporary increase in engine temperature under extreme driving conditions.

Maintenance and Long - Term Reliability

The GW4N20's electronic components in the cooling system may seem more complex, but they also offer advantages in terms of maintenance and long - term reliability. The electronic water pump has fewer moving parts compared to a mechanical water pump, reducing the risk of mechanical failures such as belt wear and tear. Additionally, the ECU's ability to monitor the performance of the cooling system in real - time allows for early detection of potential issues. For example, if the electronic water pump's flow rate drops below a certain threshold, the ECU can send an alert, allowing for timely maintenance. On the other hand, the EA888's belt - driven mechanical water pump requires regular belt inspections and replacements, which can be costly and time - consuming.

Industry Trends and Future of Engine Cooling Systems

The comparison between the GW4N20 and EA888 cooling systems also reflects the broader trends in the automotive industry. Currently, there is a growing shift towards more intelligent and efficient cooling systems. New materials such as advanced polymers and lightweight metals are being explored for use in cooling system components to reduce weight and improve heat transfer efficiency.

In terms of control technology, the use of artificial intelligence and machine learning algorithms is becoming more prevalent. These technologies can further optimize the operation of cooling systems by predicting engine temperature changes and adjusting the coolant flow rate accordingly. For example, future cooling systems may be able to learn from the driving habits of the vehicle owner and adjust the cooling system's operation to maximize efficiency.

Moreover, with the increasing popularity of electric and hybrid vehicles, cooling systems are not only required to cool the engine but also other components such as battery packs and electric motors. This presents new challenges and opportunities for the development of cooling system technology.

Conclusion

In conclusion, both the GW4N20 2.0T and EA888 third - generation 2.0T engines have their unique cooling system designs. The GW4N20's use of an electronic water pump and electronic thermostat offers advantages in fuel efficiency, cooling efficiency, and maintenance. However, the EA888's belt - driven mechanical water pump and rotary ball - valve - type cooling module also have their merits, having been proven in the market for many years. As the automotive industry continues to evolve, we can expect to see further improvements in engine cooling systems, with a focus on greater efficiency, intelligence, and adaptability.

Which cooling system do you think is more suitable for future automotive development?

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117