Water Pump Comprehensive Guide: Types, Applications, Installation & Maintenance Tips

Published:2019-07-18

What is a Water Pump and Why Does It Matter?

A water pump is a critical mechanical device that circulates or boosts liquid flow, essential for applications from household systems to industrial machinery. If you’re searching for “how water pumps work” or “which pump type suits your needs,” this guide breaks down everything from technical parameters (flow, head, efficiency) to real-world uses.

Water pump field of application:

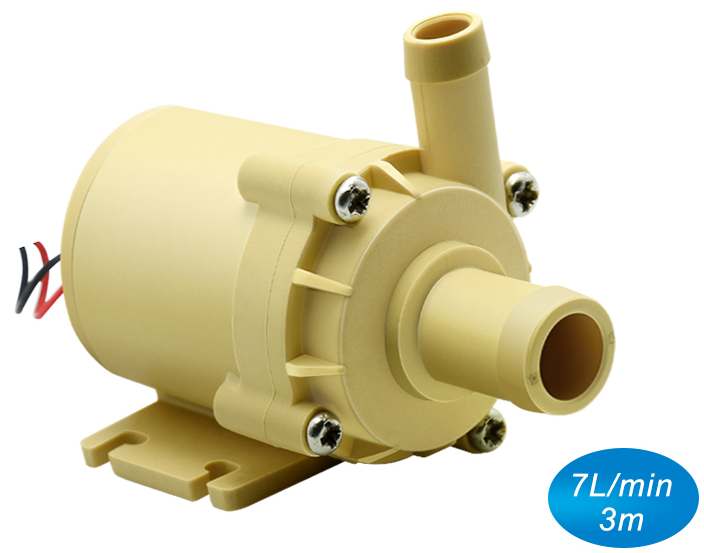

Shenpeng's dc mini water pumps, which are known for their high performance and reliability, are widely applied in various industries. In the computer cooling system, they are crucial for maintaining the optimal temperature of computer components, ensuring the stable operation of the system. For coffee machines, these pumps precisely control the water flow, enabling the extraction of rich flavors during the brewing process. In water purifiers, they play a vital role in the filtration and circulation of water, providing clean and safe drinking water. In soilless culture, they help in delivering the necessary nutrients and water to plants, promoting healthy growth. In water heaters and warm mattresses, they ensure efficient heat transfer and circulation, enhancing user comfort. In chiller machines, they contribute to the cooling process, maintaining the desired temperature. Dishwashers rely on these pumps for effective water spraying and rinsing. Intelligent toilets utilize them for functions like flushing and water circulation. In new energy vehicle cooling systems, they are essential for cooling the battery and other components, improving the overall performance and lifespan of the vehicle. These dc mini water pumps, with their unique features, are also suitable for other applications such as Key Applications in Emerging Industries:

1. EV & Energy Storage: 12V/24V DC submersible pumps for new energy vehicle battery cooling and energy storage system heat dissipation, improving battery lifespan by 30%+.*

2. Renewable Energy: Source heat pumps for geothermal heating, reducing carbon emissions in green buildings.

3. Smart Home: DC mini pumps in intelligent toilets and dishwasher water circulation systems, integrating with IoT control systems.

Water Pump Classification by Principle & Industry

| Classification Type | Examples | Industry Applications |

| Principle | Centrifugal, Axial Flow, Reciprocating | HVAC, water treatment, chemical plants |

| Industry | Petroleum pump, Medical pump, EV pump | Oil & gas, healthcare, automotive |

| Medium | Seawater pump, Acid-base pump | Marine engineering, chemical processing |

Water pump classification:

By use, water pumps have diverse classifications. Delivery pumps are designed to transport liquids over a distance, and they are widely used in industrial liquid transfer applications. Circulating pumps, such as the efficient 12v dc circulating pump, are essential for maintaining fluid circulation in systems like HVAC (Heating, Ventilation, and Air Conditioning). Fire pumps play a critical role in fire protection systems, providing the necessary pressure to deliver water in case of emergencies. Pressure test pumps are employed to test the pressure resistance of pipelines and equipment, ensuring the safety and integrity of industrial installations. Sewage pumps handle the transportation of wastewater, and metering pumps are used for precise dosing of liquids in various industrial and chemical processes. Sanitary pumps are designed to meet the strict hygiene requirements in food and pharmaceutical industries, ensuring the safe transfer of fluids. Dosing pumps are used for adding specific amounts of chemicals or substances, and gelatinization pumps are utilized in processes where gelatinization occurs. Infusion pumps are essential in medical applications for controlled drug delivery, and defoaming pumps are used to remove foam from liquids. Process pumps are designed for specific industrial processes, and oil delivery pumps are used in the petroleum industry. Water supply pumps ensure the supply of clean water, drainage pumps are used for draining water from areas, and drain pumps are designed for removing excess water. Dredge pumps are used in dredging operations, sprinkler pumps are for sprinkler systems, booster pumps increase the pressure of the water flow, high - pressure pumps are used in applications that require high pressure, insulation pumps are for maintaining the temperature of fluids, high - temperature pumps handle hot fluids, low - temperature pumps are used for cold fluids, condensate pumps are used for handling condensate, heating network pumps are part of heating systems, cooling pumps are for cooling applications, HVAC pumps are integral to heating, ventilation, and air conditioning systems, deep well pumps are used for extracting water from deep wells, pain relief pumps are used in medical pain management, chemotherapy pumps are used in cancer treatment for drug delivery, air pumps are used for moving air, blood pumps are used in medical procedures involving blood circulation, pumping pumps are used for various pumping operations, sulfur removal pumps are used in industries to remove sulfur from fluids, shear pumps are used for shearing fluids, grinding pumps are used for grinding substances in fluids, fuel pumps are used in fuel delivery systems, fish suction pumps are used in aquaculture, bathtub pumps are used in bathtubs, source heat pumps are used for heating and cooling based on renewable energy sources, filter pumps are used for filtering fluids, oxygenation pumps are used for adding oxygen to fluids, shampoo pumps are used in shampoo dispensers, injection pumps are used in injection processes, inflation pumps are used for inflating objects, gas pumps are used for handling gases, art pumps are used in artistic applications, odorization pumps are used for adding odor to fluids, chopping pumps are used for chopping substances in fluids.

Water pump classification by industry

Petroleum pump, metallurgical pump, chemical pump, fishery pump, mining pump, electric pump, water pump, water treatment pump, food pump, brewing pump, pharmaceutical pump, beverage pump, oil refining pump, seasoning pump, paper pump, textile pump, printing and dyeing pump, ceramic pump, paint pump, pesticide pump, fertilizer pump, sugar pump, alcohol pump, environmental pump, salt pump, beer pump, starch pump, water supply pump, heating pump, agricultural pump, garden pump, aquarium pump, boiler pump Medical pump, marine pump, aviation pump, automobile pump, fire pump, cement pump, air conditioning pump, nuclear pump, mechanical pump, gas pump, oil and gas mixed pump

Water pump classification by principle

Reciprocating pump, plunger pump, piston pump, diaphragm pump, rotor pump, screw pump, liquid ring pump, gear pump, sliding vane pump, roots pump, roller pump, cam pump, peristaltic pump, disturbing pump, vane pump, centrifugal pump, axial flow pump, mixed flow pump, vortex pump, jet pump, jet pump, water hammer pump, vacuum pump, spiral case pump, hose pump, worm pump

Water pump classification by media

Clean water pump, sewage pump, seawater pump, hot water pump, hot oil pump, heavy oil pump, heavy oil pump, slag pump, asphalt pump, impurity pump, slag slurry pump, mortar pump, mortar pump, slurry pump, cement pump, concrete pump, powder pump, acid-base pump, air pump, steam pump, oxygen pump, ammonia pump, gas pump, blood pump, foam pump, lotion pump, paint pump, sulfuric acid pump, hydrochloric acid pump, colloid pump, alcohol pump Beer pump, wine pump, chocolate pump, milk pump, starch pump, wort pump, toothpaste pump, brine pump, brine pump, lye pump, molten salt pump, grease pump, pesticide pump, fertilizer pump, reagent pump, gas-liquid pump, oil pump, chemical fiber pump, spinning pump, dosage pump, paint pump, fruit pulp pump, pulp pump, insulin pump, concentrated slurry pump, air pump, water pump, oil pump.

Installation method of water pump

Whether it is a 12v submersible water pump or a larger industrial pump, requires careful consideration. Firstly, try to place the water pump close to the water source as far as possible. This is beneficial to the start of the pump and shortens the length of the suction pipe. The foundation at the pump installation site must be firm. For a 24v dc pump used in a fixed pump station, a special foundation should be built. The water inlet pipe of the pump must be sealed reliably and have proper support. It cannot be simply hung on the water pump. When the inlet pipe has a bottom valve, like in the installation of a centrifugal pump, it should be installed as vertically as possible with its axis and horizontal plane, and the included angle between its axis and horizontal plane shall not be less than 45 °. If the water source is a channel, the bottom valve should be positioned more than 0.50 meters above the bottom of the water, and a screen should be added to prevent sundries from entering the pump and damaging the pump components. The base of the machine and pump, such as that of a vane pump, shall be horizontal and firmly connected with the foundation. When using belt drive for the machine and pump, ensure the tight side of the belt is lower. The direction of the pump impeller, whether it is a rotary vane pump or other types, should be consistent with the direction indicated by the arrow. When coupling transmission is adopted, the machine and pump must be coaxial. The installation position of the water pump needs to meet the requirements of the allowable vacuum suction height. The foundation must be horizontal and stable to guarantee that the rotating direction of the power machinery is in line with that of the water pump. If there are multiple units in the same machine room, for example, multiple brushless DC pumps, there should be a sufficient distance, more than 800mm, between the units and between the units and the wall. The suction pipe of the water pump must be well sealed, and the number of elbows and gate valves should be minimized. When filling water, the air should be exhausted to prevent air accumulation in the pipe during operation. The suction pipe is required to be connected with the water inlet of the water pump in a slightly upward slope, and the water inlet should have a certain submergence depth.

Precautions for water pump

Especially for sensitive pumps like the brushless DC magnetic isolation water pump, are of great importance. If any small fault occurs during the operation of water pump, do not let it continue working. For example, if the packing of water pump shaft of a submersible water pump is worn, it should be added in time. If it is allowed to continue operating, it will lead to leakage, which will directly result in increased energy consumption of the motor and potential damage to the impeller. If the pump vibrates strongly, such as a centrifugal pump, stop to check the cause immediately. Otherwise, it will cause damage to the pump body and its components. When the bottom valve of water pump leaks, for instance, in a garden pump, do not try to fill the inlet pipe with dry soil and flush the bottom valve with water. This incorrect practice can cause dry soil to enter the pump when it starts, damaging the pump impeller and bearing, and shortening the service life of the pump. Instead, when the bottom valve leaks, it must be repaired properly. If the leakage is severe, the bottom valve needs to be replaced. After using the water pump, like a solar water pump, the water in the pump should be cleaned. It is advisable to remove the water pipe and wash it with clean water. The adhesive tape on the water pump should be removed, washed with water, and dried in a well - lighted place. Avoid putting the adhesive tape in a dark and wet environment. The adhesive tape of the water pump must not be stained with oil or any sticky substances, which can affect the performance of the pump. Carefully check the impeller of the pump, whether it is a vane pump impeller or other types, for cracks and whether it is loose on the bearing. If any issues are found, repair them in time. If there is mud on the pump impeller, clean it up.

Throughout the article, we have discussed various aspects of water pumps. Different types of DC pumps, such as the 12v dc pump and 24v dc pump, have their own unique features and applications. The brushless DC magnetic isolation water pump is known for its excellent performance in terms of insulation and durability. The brushless DC motor pump and brush DC pump also have their respective advantages in different scenarios. AC pumps, on the other hand, are widely used in some traditional applications. Centrifugal pumps, including clean water pumps, sewage pumps, and slurry pumps, are crucial in fluid transportation and processing. For example, the stainless steel pump is suitable for corrosive environments, while the self - priming pump offers convenience in certain operations. The vortex pump, impurity pump, shielded pump, insulated pump, high - temperature pump, low - temperature pump, condensate pump, heating network pump, cooling pump, HVAC pump, deep well pump, pain relief pump, chemotherapy pump, air pump, blood pump, pumping pump, sulfur removal pump, shear pump.

- Distribution in Water Heater Mattresses: Why BLDC Pumps Ensure Uniform Heating

- How BLDC Pumps Ensure Precise Flow in Water Dispensers

- Why BLDC Pumps Are Essential for Smart Toilets

- The Critical Role of Automotive Electronic Water Pumps in New Energy Vehicle Battery Thermal Management

- Noise Control Technology for Smart Toilet Water Pumps: Enhancing Quiet Operation in Modern Bathrooms

- Unveiling the Working Principle of Automotive Electronic Water Valves

- Comparative Analysis of Liquid-Cooled Pumps vs. Air-Cooled Systems for EV Charging Stations

- Technical Application of Brushless DC Motors in Energy Storage Circulation Pumps

- Water Heater Pump: Efficiency Upgrade for Low-Voltage Systems

- How Dishwasher Water Pumps Enhance Cleaning Coverage Through Stable Operation?