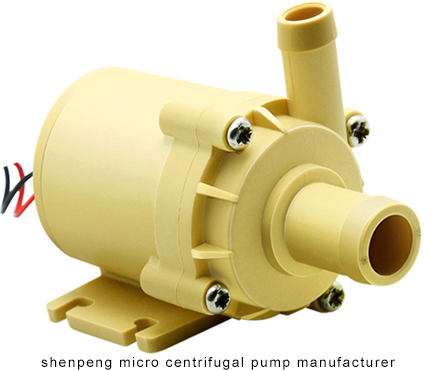

What is a centrifugal pump? - Principle and composition

Published:2022-12-15

Centrifugal pump refers to the pump that transmits liquid by centrifugal force generated when the impeller rotates.Centrifugal pump works by centrifugal movement of water caused by impeller rotation. Before starting the water pump, the pump casing and suction pipe must be filled with water, and then the motor must be started to make the pump shaft drive the impeller and water to rotate at a high speed. The water is centrifugal and thrown to the outer edge of the impeller, and flows into the pressurized water pipeline of the pump through the flow channel of the volute pump casing.

The basic structure of large centrifugal pump is composed of six parts, namely, impeller, pump body, pump shaft, bearing, sealing ring and stuffing box.

1. The impeller is the core part of the centrifugal pump. Its speed is high and its output is large. The blades on the impeller play a major role. The impeller must pass the static balance test before assembly. The inner and outer surfaces of the impeller shall be smooth to reduce the friction loss of water flow.

2. The pump body, also known as the pump housing, is the main body of the water pump. It plays a supporting and fixing role and is connected with the bracket for installing the bearing.

3. The function of the pump shaft is to connect the motor with the coupling to transmit the torque of the motor to the impeller, so it is the main part to transmit mechanical energy.

4. The sliding bearing uses transparent oil as lubricant, and oil is added to the oil level line. Too much oil will leak out along the pump shaft, and too few bearings will overheat and burn out, causing accidents! During the operation of the water pump, the maximum temperature of the bearing is 85 ° C, which is generally about 60 ° C.

5. The sealing ring is also called the leakage reducing ring.

6. The stuffing box is mainly composed of packing, water seal ring, packing barrel, packing gland and water seal pipe. The stuffing box is mainly used to close the gap between the pump housing and the pump shaft, prevent the water flow in the pump from flowing outside and prevent the air from entering the pump, and always maintain the vacuum in the pump.

Advantages of centrifugal pumps:

1. Compact construction

2. Wide range of flow and head

3. Suitable for slightly corrosive liquids

4. Multiple control options

5. Uniform flow, smooth operation, and low vibration. Foundations that do not require special damping.

6. Equipment installation, maintenance and repair costs are relatively low.

centrifugal pump price,centrifugal pump typescentrifugal pump model,centrifugal pump uses,centrifugal pump working,centrifugal pump meaning

- Distribution in Water Heater Mattresses: Why BLDC Pumps Ensure Uniform Heating

- How BLDC Pumps Ensure Precise Flow in Water Dispensers

- Why BLDC Pumps Are Essential for Smart Toilets

- The Critical Role of Automotive Electronic Water Pumps in New Energy Vehicle Battery Thermal Management

- Noise Control Technology for Smart Toilet Water Pumps: Enhancing Quiet Operation in Modern Bathrooms

- Unveiling the Working Principle of Automotive Electronic Water Valves

- Comparative Analysis of Liquid-Cooled Pumps vs. Air-Cooled Systems for EV Charging Stations

- Technical Application of Brushless DC Motors in Energy Storage Circulation Pumps

- Water Heater Pump: Efficiency Upgrade for Low-Voltage Systems

- How Dishwasher Water Pumps Enhance Cleaning Coverage Through Stable Operation?