Only by selecting the correct processing technology can we manufacture high-precision products, reduce production costs, improve production efficiency and create good benefits for enterprises. The manufacturing of water pump parts is difficult to process and the process quality is difficult to control due to the variety, complex structure and wide range of materials. So the manufacturing of water pumps demands precision engineering to ensure durability, efficiency, and compliance with industrial standards. This guide outlines the key steps in centrifugal pump manufacturing, with a focus on optimizing processes for components like impellers, pump housings, and sealing systems. The following is the key analysis:

|  |

1.Cleaning and Preparation of Pump Components

The parts for assembling the pump must be inspected and qualified, the material code symbol design drawing requirements, the surface of the parts should be cleaned, and the matching surface should be coated with engine oil. The inside of the bearing box is cleaned and coated with oil-resistant enamel, and allowed to dry naturally for 24 hours. After passing the inspection, it can enter the assembly.

2.Bearing and Shaft Assembly Techniques

The bearing is heated to 90℃-110℃ in the heating furnace and then cooled on the shaft. First install the bearing gland on the left side of the bearing box, then put the bearing and shaft assembly into the bearing box, leaning on the left bearing gland, and measure the size of the drive end bearing gland and the end face of the bearing outer ring. The CZ pump is at 0.30 -0.70mm, the gap of ZA pump is 0-0.42mm. If ZA pump bearings are used in pairs, install and use shrink nuts to lock the bearings until the outer rings of the two bearings can rotate relatively slightly to obtain an ideal clearance.

3. Assembly of mouth ring, impeller and pump body

When assembling the mouth ring with the impeller and pump body, pay attention to evenly install the mouth ring around the impeller or pump body to reduce the shape error of the mouth ring as much as possible. After installing the set screws or welding, measure the radial runout of the impeller and the mouth ring and the gap between the two. The measured value should meet the general technical conditions of pump assembly, and the out-of-tolerance parts should be trimmed.

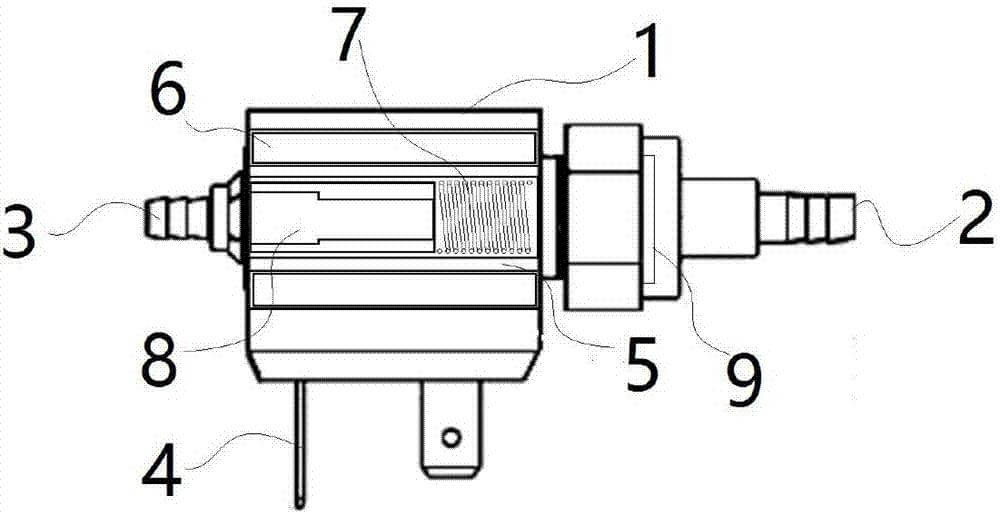

4. Sealed installation

4.1 cartridge type mechanical seal installation

When installing the cartridge mechanical seal, first install the seal on the pump cover with double-ended studs and nuts. After the pump shaft penetrates into the seal sleeve, the bearing box and the pump body are connected, and then the seal on the seal is stopped. The gasket is moved away from the bushing.

In order to reduce the abrasion of the O-ring during installation, the parts that the O-ring passes through can be lubricated, but the ethylene-propylene rubber ring should be lubricated with soap or water.

4.2 Packing seal installation

Before the packing seal is installed, the length of each circle should be determined according to the outer diameter of the shaft sleeve. After a little flattening, wrap it on the shaft sleeve and push it into the stuffing box. If there is a water seal ring, install it as required. After the packing is installed, press it evenly with a packing gland.

5. Install the impeller

For single-stage pumps, the impeller should be statically balanced and meet the technical requirements. After installing the impeller on the shaft and tightening it with a nut, put the entire rotor into the pump body and tighten it with a nut.

For multi-stage pumps, in addition to the static balance test for the impeller, a trial installation of the rotor components should be carried out. The impellers and the shaft should be assembled together, marked, and the dynamic balance test should be performed. The test results should meet the requirements of the technical conditions.

When installing, push the balance drum, shaft sleeve and all the impellers to the right until the first stage impeller and shaft sleeve lie on the shaft shoulder respectively, and measure the gap between the shaft sleeve and the balance drum to make it ≥0.5. If the gap is too small, trim the balance drum , So that the gap meets the requirements. Then install the shaft with the first-stage impeller into the inlet shell, and install the impeller and the middle shell with guide vanes onto the shaft until the outlet section. Fix the pump parts with the screw, install the balance device, seal and Bearing parts, determine the correct middle position of the rotor, and adjust the axial clearance of the tapered bearing to 0.04-0.06mm.

6. Adjustment of the bearing box of the horizontal multistage pump

The bearing housing of the non-stop positioning of the multi-stage pump should be adjusted during installation. Rotate the adjusting bolt to make the bearing box move vertically and horizontally, and measure the limit positions of the bearing box in two directions respectively, take the average value, and finally lock it with a lock nut. Hit the positioning pin, and then install the seal and bearing. The rotor is adjusted in the axial direction.

7. Coupling installation (the pump head has been fixed)

Membrane coupling installation:

Install the pump end and motor end couplings of the coupling on the corresponding shafts respectively, and use a dial indicator to correct the coaxiality of the two shafts (adjust the position of the motor with a gasket in the vertical direction) to make the diameter between the two shafts The direction jump is ≤0.1, the end jump is ≤0.05, after reaching the requirements, install the middle connection part. When the speed is> 3600 rpm, the radial runout is ≤0.05, and the end runout is ≤0.03. If the operating temperature is relatively high (approximately greater than 130°C), the final calibration should be performed under the high temperature conditions when the pump is running.

Installation of claw coupling:

Similar to the membrane coupling, the two flanges of the coupling are respectively mounted on the corresponding shafts, and the mutual positions are adjusted with a straightedge. If the rotation speed is ≥3600 rpm, it should be calibrated according to the alignment method of the membrane coupling.

8. Paint

The painting should be carried out in a clean and dry place, the ambient temperature is not lower than 5℃, and the relative humidity is not greater than 70%. If the relative humidity is greater than 70%, the paint should be added with a proper amount of moisture-proof agent to prevent the coating from whitening.

Non-steel metal parts, stainless steel parts, chrome-plated, nickel, cadmium, silver, tin and other parts: sliding parts, matching parts, sealing surfaces, ribbed surfaces, signs and steering plates are not painted.

All unprocessed surfaces and non-matching surfaces of pump parts other than the above should be painted.

centrifugal pump manufacturing process pdf,pump housing manufacturing process,impeller manufacturing process,pump manufacturers directory,pump factorio,industrial pumps,making an impeller

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117