Ability of Shenpeng Electronics Laboratory

1. Has passed CNAS certification and has a CNAS recognition certificate.

2. Passed the Changan Automobile Supplier Laboratory Accreditation System (CA-SLA), SAIC GM Wuling Supplier Test Verification and Testing Capability Accreditation Certificate, and Geely Supplier Laboratory Accreditation Certificate.

3. There are more than 50 test items available, including high and low temperature storage, operation, durability test, cold and hot shock test, constant temperature and humidity test, pump head, flow, power, efficiency verification test, pump pulse, pressure bearing, burst test, pump aging test, PCT accelerated aging test, electromagnetic vibration test, horizontal/vertical combustion test, IPX7/8 immersion test, IPX9K multi angle spray test, Medium acid salt spray test, enameled wire elongation, salt water pinhole test, etc.

4. Test equipment, with a total of over 70 sets, mainly including high-temperature test chambers for large-scale equipment; High and low temperature comprehensive test chamber, cold and hot shock test chamber, constant temperature and humidity test chamber, constant temperature water tank, pulse test machine, comprehensive aging test bench, PCT accelerated aging test machine, electromagnetic vibration test bench, horizontal/vertical combustion test, waterproof equipment, salt spray test equipment, enameled wire performance test equipment, precision oven, etc.

Introduction to Laboratory Equipment

Introduction to Environmental Testing Room

It includes comprehensive test chamber, environmental test chamber, high temperature test, pulse test chamber, cold and hot shock test chamber, constant temperature and humidity test chamber, water pump comprehensive test bench and programmable DC power supply equipment. Mainly conducting tests on high and low temperature operation, high and low temperature start and stop, resistance to humidity and heat, pressure, explosion, pulse, overvoltage, water pump performance, etc. of the product.

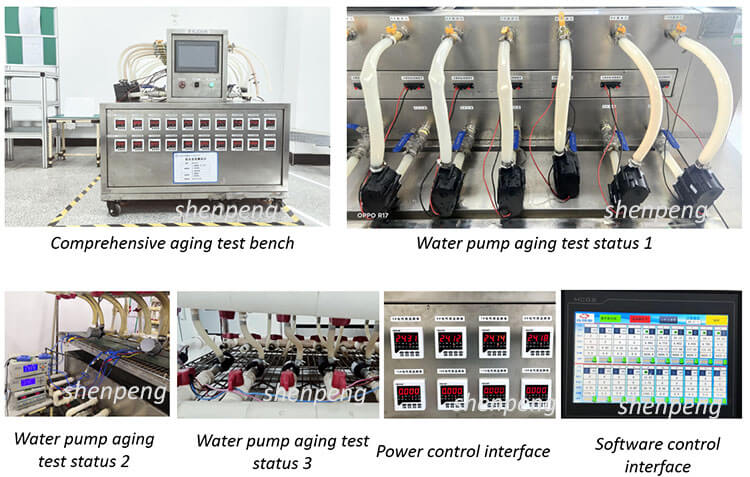

Introduction to Aging Testing Room

Equipped with a comprehensive aging test bench and a self-made aging test stand, the main function of the equipment is to activate the product operation function through certain current monitoring under a given voltage, head, and flow value, and conduct durability aging test on the product.

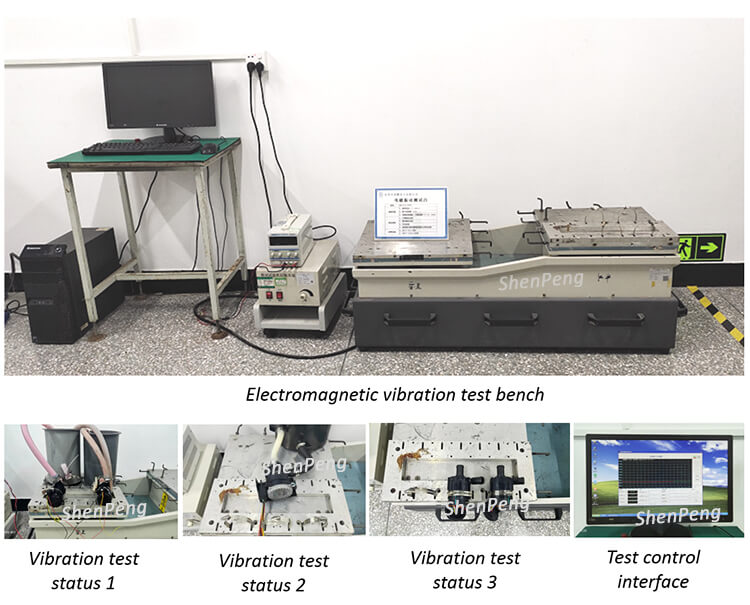

Introduction to Vibration Testing

The electromagnetic vibration test bench is designed to simulate actual working conditions for assessment and structural strength testing. Its technical parameters are:

- Frequency modulation range: 5-50HZ, 5-200HZ

- Acceleration: 0-10g

- Vibration direction (XYZ): horizontal and vertical

- Setting range (S): 1-86400

- Reference standard: GB/T2423.10

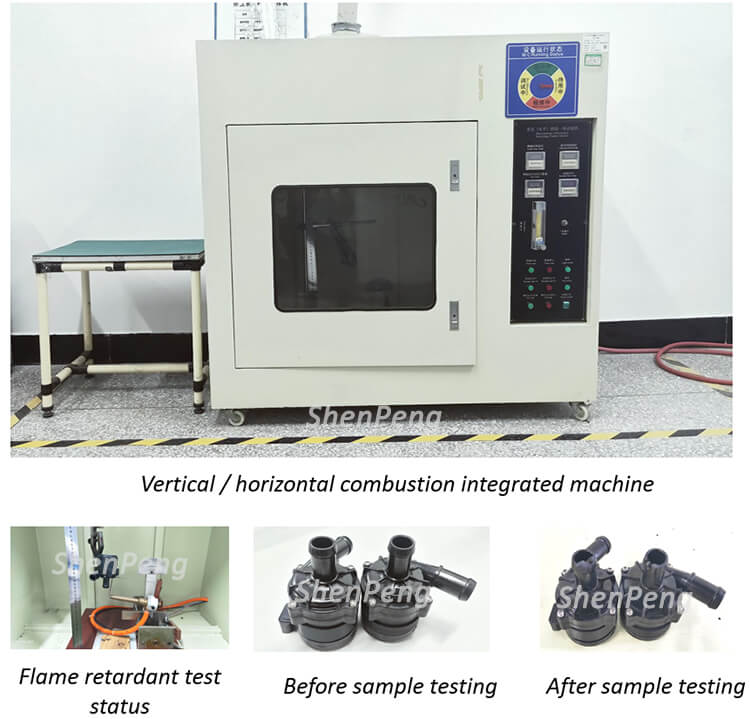

Introduction to high-temperature flame retardant testing

Vertical/horizontal combustion integrated machine, functional for flame retardant testing of materials. Its technical parameters are:

- Burning time: 0-1000 seconds, temperature range: 0-1000 ℃

- Flame height: 20-170mm, combustion angle: 0 º 45 º 90 º

- Reference standard: GB/T2408-2008

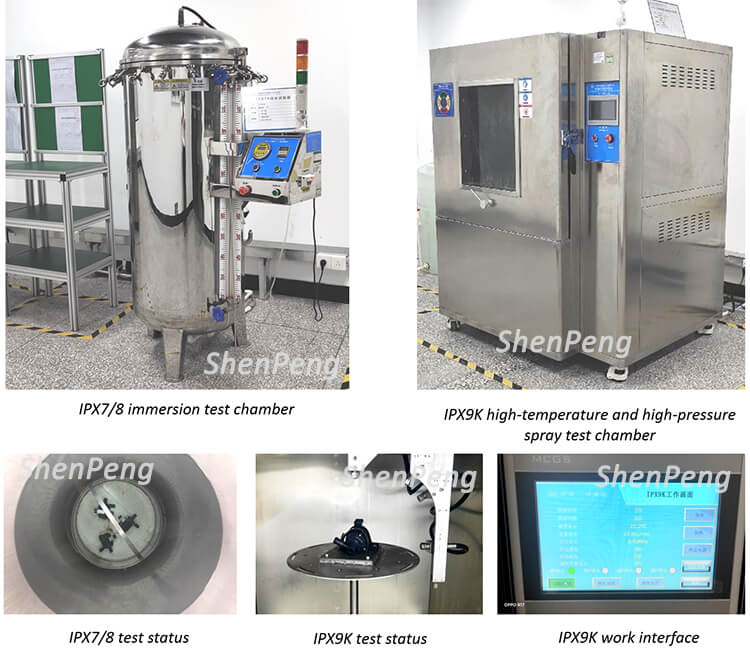

Introduction to Waterproof Testing

IPX7/8 immersion test chamber to test whether the product has strong water resistance when submerged underwater.

- Test depth: 0.5~10m Pressure range: 0~0.3Mpa

- IPX9K high-temperature and high-pressure spray test chamber, set water temperature, test bench speed, spray angle, and spray time, and conduct water spray test on the product.

- Spray angle: 0 º 30 º 60 º 90 º

- Water temperature: 0-90 ℃

- Injection pressure: 8-10MPa

- Standard: GB/T4208-2017

Introduction to Salt Spray Testing

Prepare a certain concentration of sodium chloride solution according to the standard, simulate the marine surrounding climate at a certain environmental temperature and humidity, and conduct environmental tests on the corrosion resistance performance of the product.

- Composite salt spray testing machine

- Temperature and humidity of the test chamber: 0-50 ℃, 0-100RH%

- Spray volume: 1~2ml/min

- Salt spray testing machine

- Test chamber temperature: 0-50 ℃

- Spray volume: 1~2ml/min

- Reference standard: GB/T2423.17-2008

The development of all products of Shenpeng follows the following principles:

1. All new products are based on customer needs and pass specific tests in the laboratory;

2. Our R&D engineers and product engineers work together to complete the project, which is more in line with customer needs;

3. Our company has been committed to improving the parameters, performance and quality of all products and achieving long-life needs with the most effective cost;

4. All products of our company are designed with the concept of art and beauty;

5. Our product research and development has always been committed to achieving the best competitiveness for our customers in the market.

All of Shenpeng Shenpeng's engineers and technicians insist on citing cutting-edge technology, strive to improve the existing technology level and always meet the core needs of customers, including conducting targeted tests by simulating actual operating conditions. At the same time, we also use the team's technical expertise to make relevant improvements to the product, such as reducing noise, reducing vibration, providing cooling, providing alternative replacement parts, and expanding other free services.

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117