In the intricate landscape of modern industrial and automotive technology, the electric water pump stands as a pivotal component, especially within the realm of automobile engine cooling systems. An electric water pump is tasked with the crucial responsibility of driving the circulation of coolant. Its operation is vital for absorbing the surplus heat generated by the engine and dissipating it into the external air via the radiator. This process is essential for maintaining the optimal temperature of the engine. When the engine temperature rises excessively, it can have detrimental effects on the engine's performance ad longevity. For instance, high temperatures reduce the lubricating properties of engine oil, leading to increased friction and wear between moving parts. If the temperature soars to a certain critical value, it can trigger severe malfunctions such as engine cylinder scuffing or bush burning. In extreme cases, this can ultimately result in the engine seizing up and being rendered useless.

|  |  |

Product Showcase

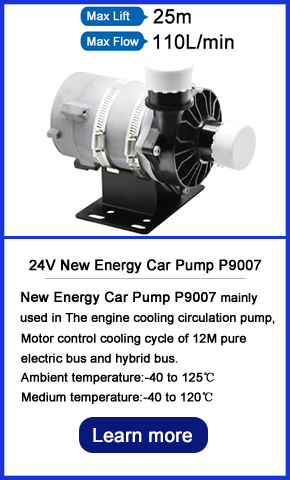

24V New Energy Car Pump P9007

The 24V New Energy Car Pump P9007 is a specialized electric water pump designed for specific applications in the automotive industry. It is primarily utilized as an engine cooling circulation pump and for motor control cooling cycles in 12M pure electric buses and hybrid buses. With a maximum lift of 25m and a maximum flow rate of 110L/min, it is engineered to meet the high - demand cooling requirements of these large - scale vehicles. The pump can operate effectively in ambient temperatures ranging from - 40 to 125°C and medium temperatures from - 40 to 120°C. Learn more about its features and performance to understand how it contributes to the efficient operation of new energy vehicles.

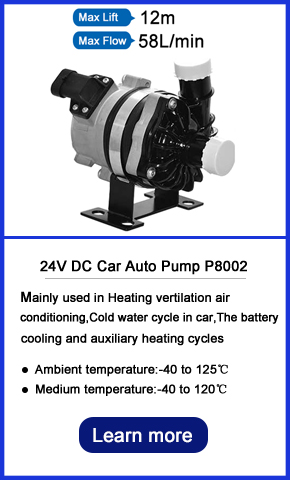

24V DC Car Auto Pump P8002

The 24V DC Car Auto Pump P8002 serves multiple functions in a vehicle's system. It is mainly used in heating, ventilation, and air - conditioning (HVAC) systems, cold water circulation within the car, as well as battery cooling and auxiliary heating cycles. Boasting a maximum lift of 12m and a maximum flow rate of 58L/min, it operates well within the same ambient and medium temperature ranges as the P9007 pump. This pump's versatility makes it an essential part of a car's overall thermal management system, ensuring passenger comfort and optimal vehicle performance. Learn more to explore its applications in different vehicle subsystems.

12V Vehicle Cooling DC Pump P6212

The 12V Vehicle Cooling DC Pump P6212 is another important offering. It is mainly deployed in heating, ventilation, and air - conditioning systems, as well as in the cooling circuits of new energy vehicles. With a maximum lift of 9m and a maximum flow rate of 35L/min, it is designed to function efficiently in a variety of operating conditions. Its ability to operate within the - 40 to 125°C ambient temperature and - 40 to 120°C medium temperature ranges makes it suitable for different climates. Discover more about how this pump meets the cooling needs of various vehicle components.

Working Principle of the Electric Water Pump

The operation of an electric water pump is a fascinating blend of electrical and mechanical engineering. The Engine Control Unit (ECU) plays a central role in regulating the pump's operation. It adjusts the duty cycle through Pulse - Width Modulation (PWM) based on various feedback signals, with water temperature being a key parameter. PWM is a technique that involves varying the width of electrical pulses to control the average power supplied to a device. In the case of an electric water pump, the ECU uses PWM to precisely control the power delivered to the pump's motor.

When the ECU receives signals indicating that the engine temperature is rising and more coolant circulation is required, it increases the duty cycle. This means that the motor receives power for a longer duration within each pulse cycle. The signal is then transmitted to the controller inside the electric water pump. The controller, in turn, interprets the duty - cycle signal and controls the rotation of the motor accordingly. As the motor rotates, it drives the impeller rotor. The impeller's rotation creates a centrifugal force that propels the coolant through the system, thus achieving the crucial task of coolant circulation. This highly - regulated process ensures that the engine's temperature is maintained within the optimal range under different operating conditions.

Composition of the Electric Water Pump

Overcurrent Unit: Function and Importance

The overcurrent unit is a critical safeguard within the electric water pump. Its primary function is to monitor the electrical current flowing through the pump. In case of an overcurrent situation, which can occur due to factors such as a blocked impeller or a short - circuit in the motor windings, the overcurrent unit quickly detects the abnormal current. Once detected, it takes immediate action to protect the pump. This may involve cutting off the power supply to the motor to prevent damage from excessive heat generated by the overcurrent. By doing so, the overcurrent unit helps to extend the lifespan of the pump and ensures its reliable operation over time.

Motor Unit: Types and Working Mechanisms

The motor unit is the heart of the electric water pump, and in most cases, a DC brushless motor is employed. DC brushless motors offer several advantages over traditional brushed motors. They have a higher efficiency, which means they can convert electrical energy into mechanical energy with less power loss. This results in lower energy consumption and reduced heat generation. Additionally, they have a longer lifespan as they do not suffer from the wear and tear associated with brushes.

The working mechanism of a DC brushless motor in an electric water pump involves the interaction between a permanent magnet rotor and an electromagnetic stator. When an electric current is passed through the stator windings, it creates a magnetic field. This magnetic field interacts with the magnetic field of the rotor, causing the rotor to rotate. The rotation of the rotor is then transferred to the impeller, which drives the coolant circulation. The speed of the motor, and consequently the flow rate of the coolant, can be precisely controlled by adjusting the electrical current supplied to the motor, as regulated by the ECU and the pump's controller.

Electronic Control Unit: Capabilities and Applications

The electronic control unit (ECU) of the electric water pump is a sophisticated component that enables a wide range of functions. It allows for the adjustment of the pump's working state based on various inputs. For example, it can control the start and stop of the pump. When the engine is cold, the ECU may delay the pump's start to allow the engine to warm up more quickly. As the engine temperature rises, the ECU can start the pump and adjust its speed to meet the cooling requirements.

The ECU also enables flow control and pressure control. By adjusting the motor speed, it can regulate the flow rate of the coolant. This is crucial for maintaining the proper cooling effect in different engine operating conditions. Additionally, the ECU provides anti - dry operation protection. If the coolant level drops too low, the ECU can detect this and stop the pump to prevent damage caused by running the pump without coolant. It also has self - maintenance capabilities, such as monitoring the pump's performance and diagnosing potential issues. The ECU can communicate with other vehicle systems, allowing for seamless integration into the overall vehicle control network.

Advantages of the Electric Water Pump

The electric water pump offers a plethora of advantages that have made it a preferred choice in various industries. Structurally, it is compact, which is a significant advantage in applications where space is at a premium, such as in modern automobiles. Its compact design allows for easy installation in tight engine compartments.

In terms of use, it is highly convenient. With its electronic control capabilities, it can be easily integrated into automated systems. For example, in a smart home water - heating system, the electric water pump can be programmed to operate at specific times or in response to temperature changes.

Functionally, it is extremely powerful. As mentioned earlier, it can perform tasks such as flow control, pressure control, and self - maintenance. This versatility makes it suitable for a wide range of applications, from automotive cooling to industrial processes.

The electric water pump also excels in terms of performance. It has a long service life, thanks to components like the DC brushless motor and the protective overcurrent unit. Its performance remains stable over time, ensuring reliable operation. It operates with low noise, which is a desirable feature in applications where noise reduction is important, such as in electric vehicles.

Energy - wise, it is highly efficient, consuming less power while delivering excellent performance. This not only reduces operating costs but also contributes to energy conservation. These combined advantages have led to the widespread adoption of electric water pumps, especially in the booming field of new energy vehicles.

Future Outlook

With the rapid advancement of industry and technology, the electric water pump is set to play an even more significant role. In the field of new energy vehicles, as the demand for higher - efficiency and more reliable cooling systems grows, electric water pumps will continue to evolve. They will likely incorporate more advanced control algorithms, such as artificial - intelligence - based temperature prediction and control, to further optimize their performance.

In addition, the application of micro - electric water pumps is emerging as a new frontier. In the fields of artificial intelligence, biotechnology, and the medical industry, these pumps can be used in various applications. For example, in medical devices such as dialysis machines, micro - electric water pumps can be used to circulate fluids precisely. In biotechnology laboratories, they can be used in microfluidic systems for handling small volumes of biological samples. This expansion of applications has far - reaching implications for the development of modern science and technology industries, driving innovation and progress.

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117