With the continuous development of automotive technology, electronic water pumps have gradually replaced traditional mechanical water pumps and become an important component of modern automotive cooling systems. This article will compare in detail the similarities and differences between automotive electronic water pumps and traditional automotive mechanical water pumps from the perspective of performance differences.

1. There are differences in the working principle and structure between automotive electronic water pumps and traditional automotive mechanical water pumps.

Automotive electronic water pump is a type of water pump driven by an electric motor, which precisely controls the flow and temperature of the coolant through an electronic control unit (ECU) and sensors. Its working principle is that the motor drives the centrifugal impeller to rotate, generating centrifugal force to suck in the coolant from the inlet and throw it towards the outlet, forming a cycle. The electronic water pump is mainly composed of three parts: fluid unit, motor unit, and electronic control unit. Its structure is relatively simple and there is no risk of mechanical friction loss or water leakage.

Traditional automotive mechanical water pumps use the engine crankshaft to drive the cam and connecting rod, causing the water pump impeller to rotate and drive the circulation of coolant. This type of water pump consists of pump bearings, water seals, impellers, synchronous pulleys, and a housing, and its structure is relatively complex. Its speed is directly affected by the engine speed and cannot be flexibly adjusted according to cooling requirements.

2. The performance differences between automotive electronic water pumps and traditional automotive mechanical water pumps are as follows:

1) Precise control of differences:

The biggest advantage of automotive electronic water pumps is that they can accurately control the flow and temperature of the coolant through ECU based on the real-time cooling requirements of the engine. This precise control not only improves the performance and efficiency of the engine, but also effectively reduces energy consumption and emissions. However, traditional mechanical water pumps cannot be flexibly adjusted according to the specific needs of the engine, often resulting in waste or insufficient cooling capacity.

2) Energy consumption and efficiency differences:

In terms of energy consumption, automotive electronic water pumps have lower energy consumption compared to mechanical water pumps due to their use of motor-driven systems. The traditional mechanical water pump for cycling requires the engine to be driven by the crankshaft, which increases additional power consumption. In addition, the working efficiency of automotive electronic water pumps is also higher, with lower noise, further improving driving comfort.

3) Differences between intelligence and stability:

The automotive electronic water pump has a high degree of intelligence, which can automatically adjust the working state according to different working conditions and temperature modes, and maintain the optimal cooling effect of the engine. Meanwhile, due to the fact that automotive electronic water pumps are not affected by external factors such as electromagnetic interference, their stability is also higher. In contrast, traditional automotive mechanical water pumps have poor stability under complex working conditions and are easily affected by factors such as electromagnetic interference.

4) Maintenance and lifespan:

In terms of maintenance and lifespan, traditional automotive mechanical water pumps, although structurally complex, are relatively easy to maintain and have a longer service life. However, once a malfunction occurs, it often requires replacing the entire water pump component, which is costly. Although the maintenance of automotive electronic water pumps is relatively difficult, their structure is simple and the maintenance cost is low. Meanwhile, due to its high efficiency and low energy consumption, it also extends the service life of the overall cooling system.

3. Application prospects:

With the popularization of new energy vehicles and high-end cars, the application prospects of automotive electronic water pumps are becoming increasingly broad. Its high efficiency, precision, and intelligence not only improve the performance and efficiency of the engine, but also reduce energy consumption and emissions. In the future, with the continuous advancement of technology and further cost reduction, automotive electronic water pumps are expected to become a standard configuration for automotive cooling systems.

4. Advantages of Shenpeng Automotive Electronic Water Pump:

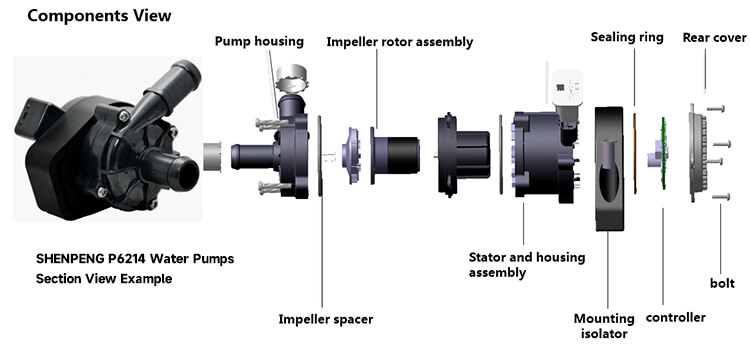

The Shenpeng automotive electronic water pump consists of a pump casing, impeller, sealing ring, motor casing, electrical plug, motor assembly, bearing, rotor, controller, control seat, rear cover, fixing bolts, etc., as shown in the figure.

The performance of automotive electronic water pumps is not only determined by excellent structural design, but also by the selection of suitable materials, which directly affects whether the automotive electronic water pump can operate normally. The commonly used material for components in automotive electronic water pumps is polyphenylene sulfide (PPS) material, which is the most cost-effective special engineering plastic. It has high temperature resistance, dimensional stability and is not easily deformed, excellent electrical performance, chemical corrosion resistance, flame retardant UL94V-O level, excellent electrical insulation performance, hydrolysis resistance and other comprehensive properties. At the same time, modified PPS endows it with high fluidity, high toughness, high wear resistance, high strength, refrigerant resistance, high CTI, low dielectric and other characteristics, ensuring the reliability of electronic water pump operation.

The shell of the automotive electronic water pump requires strong bonding with metal, resistance to antifreeze, high strength, high welding line strength (to avoid product cracking during storage), hydrolysis resistance, and PPS material can meet its material requirements. It is injection molded as a whole, easy to process, and has strong structural stability and is not easily deformed. The motor casing is made of high toughness PPS material, which can achieve the effect of improving high-power air leakage and cracking.

The impeller is molded by PPS injection molding, which is characterized by high strength, flame retardancy, high temperature resistance, high toughness, stable size, and long service life. The water pump rotor is injection molded with PPS, which has the characteristics of high wear resistance and high strength.

Electronic water pumps are highly favored by professionals due to their compact structure, easy use, powerful functions, long lifespan, stable performance, low noise, low energy consumption, high efficiency, and many other advantages.

5. Summary

In summary, there are significant differences in performance between automotive electronic water pumps and traditional automotive mechanical water pumps. Electronic water pumps have gradually replaced traditional mechanical water pumps as an important component of modern automotive cooling systems due to their precise control, low energy consumption, high efficiency, and intelligence. With the continuous development of automotive technology, the application prospects of automotive electronic water pumps will be even broader.

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117