What is an Automotive Electric Water Pump?

An automotive electric water pump is a sophisticated and crucial component within the automotive engine cooling system. It is not just a simple centrifugal pump but a highly engineered device that plays a vital role in maintaining the optimal operating temperature of the engine.

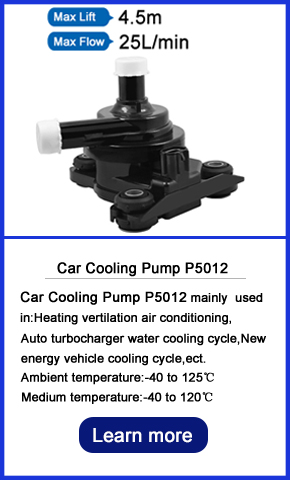

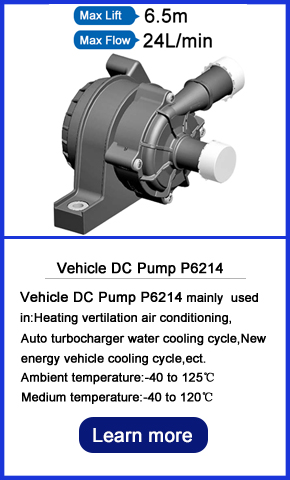

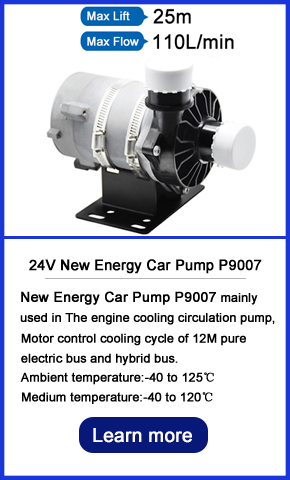

|  |  |

|  |  |

Definition and Function

The automotive electric water pump is designed to circulate coolant throughout the engine, effectively dissipating the heat generated during the combustion process. This helps in preventing the engine from overheating, which can lead to severe damage and reduced performance. In modern vehicles, especially in new - energy cars, the electric water pump has become an essential part of the thermal - management system, ensuring the efficient operation of various components such as the engine, battery, and electric motor.

Types and Classifications

Automotive electric water pumps can be classified into different types based on various factors. One common classification is by the voltage they operate on, with 12V and 24V being the most prevalent. 12V pumps are often used in smaller vehicles or in applications where power requirements are relatively low, such as in some gasoline - powered cars. 24V pumps, on the other hand, are more suitable for larger vehicles, commercial trucks, and electric vehicles that require a higher - power coolant circulation system to meet the demands of more substantial heat - generating components.

Another way to classify them is by their design and construction. Some electric water pumps feature a brushless DC motor, which offers advantages like higher efficiency, longer lifespan, and reduced maintenance compared to traditional brushed motors. Others may have a different impeller design, such as a centrifugal impeller with varying blade shapes and sizes, depending on the specific requirements of the cooling system.

Working Principle of Automotive Electric Water Pumps in Detail

The Core Working Mechanism

The working principle of an automotive electric water pump is based on the conversion of electrical energy into mechanical energy to drive the flow of coolant. When the vehicle's ignition is turned on, the electric motor of the water pump receives power. In most cases, it is a DC motor, which can be either a brushed or brushless type.

The motor shaft is connected to an impeller. When the motor rotates, it drives the impeller at high speed. The impeller is typically designed with curved blades. As the impeller spins, it creates a centrifugal force. This force causes the coolant to be drawn into the center of the impeller from the inlet. Once inside, the coolant is accelerated by the rotating impeller and is then pushed outwards towards the outlet at a higher velocity. The continuous rotation of the impeller ensures a steady flow of coolant through the pump.

Operation in Different Vehicle Conditions

Under normal driving conditions, the automotive electric water pump maintains a consistent flow rate to keep the engine at its optimal temperature. For example, during city driving with frequent stops and starts, the pump adjusts its speed to match the varying heat loads of the engine. When the engine is idling, the pump may operate at a lower speed to conserve energy, while during high - speed or high - load driving, it increases its speed to provide sufficient coolant flow for effective heat dissipation.

In hybrid and electric vehicles, the electric water pump also plays a crucial role in cooling the battery pack and the electric motor. The pump ensures that these components are kept within their optimal temperature ranges, which is essential for their performance and longevity. For instance, in cold weather, the pump may be used to pre - heat the battery before driving to improve its efficiency, and in hot weather, it works to prevent the battery from overheating.

Applications of Automotive Electric Water Pumps

Engine Cooling System

The primary application of automotive electric water pumps is in the engine cooling system. They are responsible for circulating coolant through the engine block, cylinder head, and radiator. In a gasoline - powered engine, the coolant absorbs heat from the engine components and then transfers it to the radiator, where it is dissipated into the atmosphere. The electric water pump ensures that the coolant is constantly moving, maintaining a stable temperature and preventing hot spots within the engine.

Battery Cooling in Electric Vehicles

In electric vehicles, the battery is a critical component that generates heat during charging and discharging. The automotive electric water pump is used to cool the battery pack. By circulating a coolant through a cooling circuit integrated with the battery, the pump helps in maintaining the battery's temperature within the optimal range. This not only improves the battery's performance but also extends its lifespan. For example, in a long - distance electric vehicle journey, the electric water pump ensures that the battery remains at a suitable temperature, preventing any potential damage due to overheating.

Thermal Management of Hybrid Vehicles

Hybrid vehicles have a more complex thermal - management system as they need to cool both the internal combustion engine and the electric drive components. The automotive electric water pump is used to manage the coolant flow to different parts of the vehicle. It can divert coolant to the engine when it is running and to the electric motor and battery when they are in use. This helps in optimizing the overall performance of the hybrid vehicle and reducing energy consumption.

Advantages of Automotive Electric Water Pumps

High Working Pressure

Automotive electric water pumps are capable of generating high working pressures. The electric motor provides a consistent and powerful driving force, allowing the pump to push the coolant through the engine's cooling channels with sufficient pressure. This high - pressure coolant flow ensures that heat is effectively transferred from the engine components to the coolant. For example, in high - performance engines that generate a large amount of heat, the high - pressure output of the electric water pump enables better heat dissipation, maintaining the engine's performance even under extreme conditions.

Low Energy Consumption

Compared to traditional mechanical water pumps, automotive electric water pumps consume less energy. They are designed to operate at specific speeds based on the cooling requirements of the vehicle. For instance, when the engine is cold - starting or running at low loads, the electric water pump can operate at a lower speed, consuming less power. In contrast, mechanical water pumps are driven directly by the engine, consuming a significant amount of engine power regardless of the cooling needs. The energy - efficient operation of electric water pumps also contributes to better fuel economy in gasoline - powered vehicles and longer - range capabilities in electric vehicles.

Low Friction

Automotive electric water pumps have significantly lower friction compared to their mechanical counterparts. The use of advanced materials and design techniques reduces friction between moving parts. For example, brushless DC motors used in electric water pumps have fewer mechanical contact points, minimizing friction and wear. Additionally, the impeller design is optimized to reduce friction with the coolant, improving the overall efficiency of the pump. This low - friction operation not only extends the lifespan of the pump but also reduces the energy required to operate it.

Low Risk of Leakage

The design of automotive electric water pumps reduces the risk of leakage. In traditional mechanical water pumps, the impeller is installed on the pump bearing through an interference fit, which can lead to leakage over time due to wear and tear. In electric water pumps, many models use an integrated magnetic impeller driven by a magnetic core installed on the pump casing. This design separates the water chamber from the outside, eliminating the need for a traditional water seal. As a result, the risk of friction - induced wear and water leakage is greatly reduced, ensuring a more reliable and leak - free operation.

Long Service Life

Automotive electric water pumps are built to last. With proper maintenance, they can work continuously for over 20,000 hours under normal operating conditions. The use of high - quality materials, such as corrosion - resistant pump casings and durable motor components, contributes to their long lifespan. Their long - term reliability is crucial for the smooth operation of automotive engines, as a malfunctioning water pump can lead to engine overheating and costly repairs.

Industry Trends and Future of Automotive Electric Water Pumps

Integration of Smart Technology

The future of automotive electric water pumps lies in the integration of smart technology. Manufacturers are increasingly equipping electric water pumps with sensors and control systems. These sensors can monitor various parameters such as coolant temperature, flow rate, and pump speed in real - time. The data collected is then used to adjust the pump's operation automatically. For example, if the sensor detects a rise in engine temperature, the control system can increase the pump's speed to provide more coolant flow, ensuring optimal engine cooling.

Development of Energy - Saving and Environment - Friendly Technologies

As the automotive industry moves towards greater energy efficiency and environmental sustainability, electric water pumps are also evolving. New energy - saving technologies, such as more efficient motors and improved impeller designs, are being developed. Additionally, manufacturers are exploring the use of sustainable materials in pump construction to reduce the environmental impact. These developments will not only improve the performance of automotive electric water pumps but also contribute to the overall reduction of energy consumption and emissions in the automotive sector.

In conclusion, automotive electric water pumps are a vital part of modern vehicle systems. Their unique working principle, wide range of applications, and numerous advantages make them an essential component for ensuring the reliable and efficient operation of vehicles. As technology continues to advance, we can expect even more innovative features and improvements in automotive electric water pumps.

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117