I. Basic Overview of Brushless DC Water Pumps

Miniature brushless DC water pump is a machine that uses direct current ranging from 3V to 24V to drive the operation of a brushless motor. To learn more about the research details of motor drive principles, click here.The rotation of the brushless motor then drives the impeller to rotate, thereby increasing the liquid pressure to achieve the function of liquid transmission.

Compared with other types of water pumps, brushless DC water pumps exhibit many characteristics. Firstly, efficient brushless DC water pumps are outstanding in terms of high efficiency. Due to being driven by brushless motors, they possess the features of high efficiency and high speed, which can improve the working efficiency of the water pump, effectively save energy, and reduce energy waste. Secondly, the noise is very low. The motor driving structure is relatively simple, and the noise generated during operation is extremely small, having little impact on the surrounding environment and people. Thirdly, they have a relatively long service life. Since there are no vulnerable parts such as carbon brushes and electromagnets in traditional motors, their lifespan is extended compared to that of traditional water pumps. Fourthly, the energy-saving effect is remarkable. Adopting an efficient and energy-saving motor driving method can reduce energy consumption.

In addition, some brushless DC water pumps use electronic components for commutation instead of carbon brushes. They adopt high-performance wear-resistant ceramic shafts and ceramic shaft sleeves. The shaft sleeves are integrated with magnets through injection molding to avoid wear, further enhancing the service life of the water pump. Moreover, the stator and rotor parts are completely isolated. The stator and circuit board parts are encapsulated with epoxy resin, possessing 100% waterproof characteristics. The rotor part uses permanent magnet materials. The body of the water pump is made of environmentally friendly materials, has a small volume, and stable performance. It can also adjust various required parameters through the winding of the stator, can operate under a wide voltage range, and can even be installed underwater, and can play a good role in scenarios such as hot water circulation.

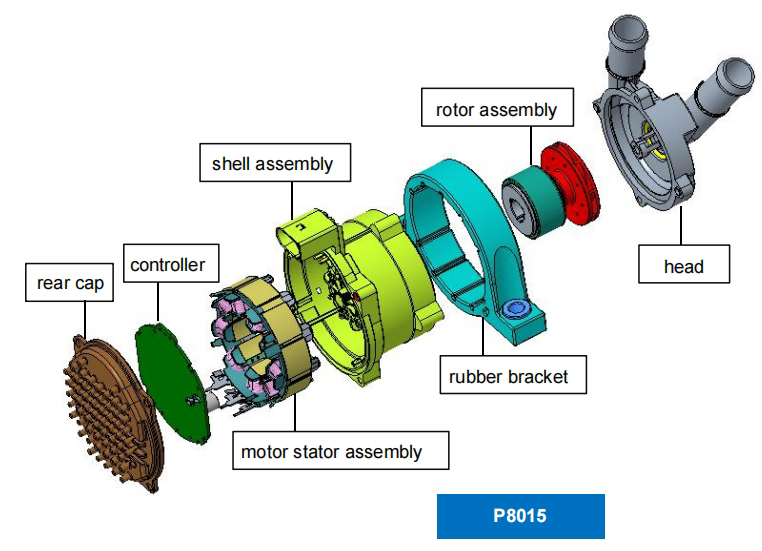

II. Core Components of Brushless DC Water Pumps

(1) Rotor

The rotor of a brushless DC water pump is the power part of the water pump. Miniature brushless DC water pump's rotor generally uses permanent magnet materials such as neodymium - iron - boron (NdFeB) magnets and samarium - cobalt (SmCo) magnets.To view the detailed characteristics of these permanent magnet materials, click here. These materials have high magnetic energy products, good magnetic stability, and corrosion resistance, and can operate stably under high rotation speeds, high temperatures, and harsh environments. Miniature brushless DC water pump's rotor is more advantageous compared with the rotor of a traditional AC asynchronous motor (which is composed of an iron core and aluminum guide bars). It has no resistance loss and eddy current loss, has higher efficiency, is lighter in weight and has smaller inertia, and can exhibit excellent mechanical properties during high - speed operation. Meanwhile, the brushless motor controller can control the torque and rotation speed in real time, making the system have excellent dynamic responsiveness, enabling rapid response and precise control. Coupled with the use of high-performance permanent magnet materials, it has a relatively long service life. During operation, the rotating magnetic field generated by the stator interacts with the magnetic field of the rotor permanent magnet, causing the rotor to start rotating and driving the impeller to rotate, thereby realizing the basic function of the water pump.

(2) Stator

Miniature brushless DC water pump's stator is the part that generates the electromagnetic field and is mainly composed of coils and so on.. When current passes through the stator coils, a magnetic field will be generated. This magnetic field will interact with the magnetic field of the rotor permanent magnet to drive the rotor to rotate and then drive the water pump to work. The design of the stator's coil winding and the power-on situation determine key elements such as the direction and intensity of the generated magnetic field. Miniature brushless DC water pump's stator, through the precise control of the current flowing into the stator coils by the motor control circuit, can generate a rotating magnetic field with a uniformly changing direction, cooperating with the rotor to achieve the stable and continuous operation of the miniature water pump. It is an indispensable key component for the normal operation of the brushless DC water pump.

(3) Motor Control Circuit

The motor control circuit plays a vital role in the miniature brushless DC water pump. It is like the "brain" of the water pump. By controlling the magnitude and direction of the current and voltage, it can precisely regulate the rotation of the rotor. Miniature brushless DC water pump's motor control circuit, for example, can detect the position of the motor rotor in real time, and then supply corresponding currents to different phases of the motor according to the position of the rotor, so that the stator can generate a rotating magnetic field with a uniformly changing direction, and the motor can rotate following the magnetic field. Moreover, during the operation of the water pump, in the face of different working condition requirements, the motor control circuit can also adjust parameters such as the rotation speed and torque of the motor to ensure that the water pump can work stably and efficiently under various conditions and ensure that the entire water pump system operates according to preset requirements.

(4) Bearing

Miniature brushless DC water pump's bearing mainly plays the roles of supporting the rotor and reducing friction. miniature brushless DC water pump's commonly used bearing materials include engineering plastic polyoxymethylene (POM) or ceramics due to their suitability for miniature applications. POM and ceramics have good heat resistance, corrosion resistance, and friction resistance properties, so they are often used to make bearings. However, due to the brittle nature and small expansion coefficient of engineering ceramics, the bearing clearance should not be too small to avoid shaft seizure accidents. In addition, the sliding bearings of magnetic pumps are lubricated by the medium being transported. Therefore, in practical applications, different materials will also be selected to make bearings according to different media and operating conditions. Appropriate bearings can effectively reduce the resistance when the rotor rotates, improve the smooth operation of the water pump, and extend the service life of the water pump.

(5) Housing

Miniature brushless DC water pump's housing plays a protective role for the internal structure, protecting it from the interference and damage of external environmental factors. In different usage scenarios, the miniature housing of the brushless DC water pump needs to possess different characteristics. For example, in some environments where it may come into contact with water, the miniature housing should have waterproof characteristics essential for miniature pump's durability to prevent water from entering the interior and damaging key components such as motors and circuits. In application scenarios with certain pressure requirements, the housing also needs to have sufficient compressive capacity to ensure the safety and stability of the internal structure. Moreover, the housings of some brushless DC water pumps are made of environmentally friendly materials and have a small volume, which also meets the characteristics of being used in some occasions with requirements for space and environmental protection.

(6) Pump Body

Miniature brushless DC water pump's pump body is the fluid part and is mainly composed of components such as the inlet, outlet, and impeller. The inlet is responsible for introducing the liquid that needs to be transported, and the outlet discharges the liquid that has been pressurized by the impeller. miniature brushless DC water pump's impeller, as a core component, rotates at a high speed under the drive of the rotor, enabling the liquid entering the miniature pump body to obtain energy and increase in pressure, and then be smoothly transported out through the outlet. The various components cooperate with each other to jointly complete the functions of liquid transportation and pressurization, ensuring that the water pump can effectively transport the liquid from one place to another to meet the corresponding usage requirements.

(7) Impeller

The impeller, as the rotor part of the water pump, is the key to realizing the movement of water. There are various choices for the material of the impeller. For example, polyphenylene sulfide (PPS) material has become one of the preferred materials for the impeller of electronic water pumps including miniature brushless DC water pumps due to its advantages such as being able to maintain stable mechanical properties at temperatures as high as 200 °C or even higher, having extremely low hygroscopicity, and having relatively high mechanical strength. Stainless steel is also often used to manufacture water pump impellers because of its multiple advantages such as corrosion resistance, wear resistance, and impact resistance. From the perspective of shape, there are different types of impellers such as backward - curved blade type, radial blade type, and forward - curved blade type. Different shapes have different impacts on performance aspects such as theoretical head, dynamic pressure head, and the efficiency of the miniature brushless DC water pump. For example, centrifugal water pumps and large fans mostly adopt the backward-curved blade type in order to increase efficiency or reduce noise levels. While for small and medium-sized fans when efficiency is not the main consideration factor, the forward-curved blade type may be adopted because under the same pressure head, the wheel diameter and outer shape can be made smaller. The impeller realizes the functions of liquid transportation and pressurization of the water pump by driving the surrounding water to move through its own high-speed rotation.

(8) Position Sensor (Optional Component)

The position sensor plays an important role in miniature brushless DC water pumps equipped with it. It can assist the motor in commutation and other related work. Miniature brushless DC water pump's position sensor, during the operation of the water pump, as the rotor rotates, will monitor the position of the rotor in real time and feed back the corresponding signals to the motor control circuit, enabling the control circuit to accurately control the on - off and direction change of the current in the stator coils according to this information, so that the magnetic field generated by the stator can be precisely matched with the position of the rotor, ensuring the continuous and stable rotation of the rotor. However, some brushless DC water pumps also adopt a design without a position sensor and use other control means to achieve the commutation and other functions of the motor. Nevertheless, the presence or absence of the position sensor does have an impact on the control precision, complexity, and cost of the overall operation of the water pump.

miniature brushless DC water pumps, with their advanced components and remarkable features, are expected to have a wide range of applications in various industries in the future

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117