Best 12V Water Pumps of 2025: Ultimate Buyer's Guide & Top Applications

A 12V water pump is a type of water pump that is driven by a 12 volt voltage and is typically used in fields such as automobiles, agriculture, and industrial applications. This type of water pump has the advantages of high efficiency, reliability, portability, and ease of maintenance, making it widely used in various occasions.

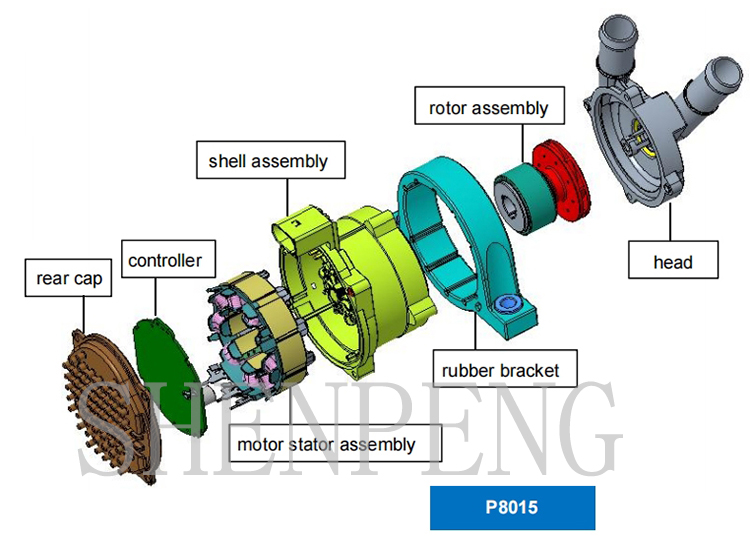

The working principle of a 12V water pump is to convert electrical energy into mechanical energy through electromagnetic induction, thereby driving water flow. It consists of an electric motor and a pump body, which generates rotational force through the interaction of magnetic field and current, driving the rotor inside the pump body to rotate, thereby sucking water in from the inlet and discharging it from the outlet.

The advantages of a 12V water pump include efficiency, reliability, portability, and ease of maintenance. Firstly, it uses a 12 volt voltage, resulting in lower energy consumption and higher efficiency. Secondly, as it is a mechanical device, it can provide reliable water flow. In addition, the 12V water pump is small in size, lightweight, easy to carry, and easy to move. Finally, its structure is simple and easy to maintain and repair.

The application range of 12V water pumps is very wide. In the automotive industry, it is used to provide water sources for the cooling, heating, and air conditioning systems of vehicles. In the agricultural field, it can be used for irrigation and pesticide spraying. In the industrial field, it can be used to cool machines and equipment, as well as to transport water and other liquids in various process flows.

All standard 12v water pump by SHENPENG with lower price you will find here:

|  |  |

Want to learn more?

The largest manufacturer of 12V water pumps in China

Guangdong Shenpeng Technology Co., Ltd.was found in 2012 and is specialized in brush-less DC water pumps. As a global BLDC water pump solutions specialist, it integrates R&D, manufacture with sales.The products are mainly applied to New-energy vehicle, mattress, home appliance (water heater, dish washer, coffee machine, water dispenser), smart toilet, cosmetic/medical equipment, machine tool equipment, air conditioning base station, PC, LED cooling system etc.

Shenpeng was the earliest company that managed to produce the brushless DC water pumps. It is located in Changping, Dongguan and covers an area of 12000㎡. With an in-house CNAS standard laboratory, 300-thousand-grade dust-free workshop and 10 professional production lines. The annual production capacity is more than 5 million sets of water pumps and it is one of the largest manufacturer of BLDC water pump in China. It won many honorable titles such as High-tech Enterprise, Multiplication Enterprise etc.

Most 12V water pumps are centrifugal pumps driven by DC motors. Their working principle is based on a series of complex and sophisticated physical processes, involving the coordinated operation of multiple key components.

Starting from the power source, when a 12V DC power supply is connected, the electromagnetic windings inside the motor generate a magnetic field due to the passage of electric current. According to the law of electromagnetic induction, this magnetic field interacts with the permanent magnet inside the motor to form a driving torque, causing the rotor to rotate at a high speed. This conversion of electrical energy into mechanical energy is the initial energy source for the operation of the water pump. The rotational speed of the motor is directly related to the performance of the water pump. The higher the speed, the more mechanical energy is output per unit time, providing more powerful power for the subsequent liquid transportation.

The impeller, as a core component, is closely connected to the motor rotor and rotates synchronously at a high speed. When the curved blades on the impeller rotate, they exert a continuous and strong force on the surrounding liquid. From a microscopic perspective, there is friction between the blades and the liquid molecules, and this friction drives the liquid molecules to move together. Macroscopically, the liquid rapidly diffuses from the center of the impeller to the edge under the action of centrifugal force. During this process, the kinetic energy of the liquid continuously increases, and its speed significantly improves. At the same time, as the liquid is squeezed to the edge of the impeller, the pressure gradually rises, and the liquid gains pressure energy. This is a crucial link for the liquid to obtain the power for transportation.

The pump body provides the physical space and guiding mechanism for the entire working process. Its internal structure is specially designed to accurately collect the liquid that is rapidly ejected from the edge of the impeller. The flow channels of the pump body are designed based on the principles of fluid dynamics, aiming to minimize the flow resistance of the liquid and reduce energy losses. Based on Bernoulli's equation, it ensures that the energy conversion among pressure, flow rate, and height remains efficient and stable when the liquid flows inside the pump body, guaranteeing the smooth flow of the liquid to the water outlet. In high - performance 12V water pumps, the pump body is optimized through computer - aided fluid dynamics (CFD) technology. By simulating the fluid flow under different working conditions, the guiding efficiency of the pump body for the liquid and the energy utilization efficiency are further improved.

Although the sealing device does not directly participate in the energy conversion and the generation of the power for liquid transportation, it is crucial for maintaining the normal working environment of the water pump. Mechanical seals use precisely machined dynamic and static rings to form a closely fitting sealing surface during relative motion, preventing liquid leakage. Rubber seals, with the high elasticity of rubber, fill the tiny gaps between the pump body and the rotating components to achieve a good sealing effect. The existence of the sealing device ensures the stability of the internal pressure of the water pump, prevents pressure losses and energy waste caused by leakage, and ensures the continuity and stability of the water pump's operation.

The complete working process of a 12V water pump is as follows: When the power is turned on, the motor drives the impeller to rotate, endowing the liquid with centrifugal force. The liquid is thrown from the center of the impeller to the edge, enters the pump body, and flows along a specific flow channel to the water outlet. At the same time, due to the continuous ejection of the liquid from the center of the impeller, a low - pressure area is formed at the center of the impeller. According to Pascal's law, under the action of the external atmospheric pressure or other pressure sources, the liquid at the water inlet is continuously sucked into the pump, realizing the continuous cyclic transportation of the liquid.

Application scope of 12v water pump?

1. Automotive Industry

In automotive cooling systems, 12V water pumps are essential for maintaining the engine temperature within an optimal range. They ensure that the engine does not overheat during operation, which is crucial for its performance and longevity. Additionally, they are also used in automotive cleaning systems, providing the necessary water flow for effective cleaning.

2. Household Appliances

- Water Heaters: In certain small - scale household water heaters, 12V water pumps are employed to facilitate water circulation or supply the required pressure. This helps in ensuring a consistent and hot water supply.

- Smart Toilets: Some smart toilet systems rely on 12V water pumps for drainage and circulating water supply. They contribute to the proper functioning of the toilet's flushing and cleaning mechanisms.

- Dishwashers: These pumps are an integral part of the water - circulation system in dishwashers. By constantly circulating water, they ensure that dishes are thoroughly cleaned, enhancing the cleaning efficiency.

- Water - Heated Mattresses: 12V water pumps are used in the water - circulation system of water - heated mattresses. They help in distributing warm water evenly throughout the mattress, providing a comfortable and warm sleeping environment.

- Coffee Machines: In both commercial and household coffee machines, 12V water pumps are responsible for transporting water. This enables the extraction of coffee essence, ensuring a rich and flavorful coffee - making process.

- Washing Machines: In some washing machines, 12V water pumps are used for water conveyance and circulation. They play a key role in the washing and rinsing cycles, ensuring that clothes are properly cleaned.

3. Industrial Equipment

- Industrial Chillers: In industrial cooling systems, 12V water pumps are used to maintain the normal operating temperature of equipment. They help in dissipating heat generated during industrial processes, ensuring the smooth running of machinery.

- Laser Machines and Printers: Some laser machines and printers use 12V water pumps to cool the laser or print head. This is crucial for preventing overheating, which could otherwise affect the quality of printing or laser - processing.

- Air - Conditioning Equipment: In air - conditioning systems, 12V water pumps are used for water circulation or cooling purposes. They contribute to the efficient operation of the air - conditioner, maintaining a comfortable indoor temperature.

4. Other Applications

- Computers: They find application in some computer water - cooled cooling systems. These pumps help in dissipating the heat generated by the computer's components, ensuring stable operation and preventing performance degradation.

- Medical and Beauty Equipment: In certain medical and beauty equipment, 12V water pumps are used for liquid transportation. This is vital for the proper functioning of these devices, whether it's for delivering treatment fluids or for maintaining the equipment's internal environment.

- Water Dispensers: 12V water pumps are used in the water - supply system of water dispensers. They ensure a continuous and convenient supply of water.

- Household Tap Water Pressurization: In some household tap - water pressurization systems, 12V water pumps are employed to increase the water pressure, providing better water flow for daily use.

- Food Processing Industry: In some food - processing equipment, 12V water pumps are used for liquid conveyance or cooling. They are essential for maintaining the quality and safety of food products during processing.

Overall, the 12V water pump plays a crucial role in many fields, providing convenient and efficient water - flow transportation solutions. Its wide - ranging applications highlight its significance in modern - day living and industrial production.

How to Choose a 12v Water Pump?

There are various 12v water pumps on the market, but not every 12v water pump can meet your requirements. This is because different 12v water pumps are suitable for different industries. Therefore, when selecting 12v water pumps, we should first clarify their scope of use, and then select different sizes, import and export forms and directions, different working performance, working environmental conditions, etc. according to the characteristics of 12v water pumps. 12v water pump with pressure switch

1. 12v water pump water head.

The maximum head of 12v water pump generally refers to the static head without water flow when pumping water to the maximum head. If it is necessary to pump to a certain height and maintain a certain flow, the required head must be higher than the specified pumping height. Generally speaking, when selecting the model, 12v water pump is necessary to increase the head to about 5% ~ 10% of the margin.

2. 12v water pump water flow.

Flow is one of the important performance data of 12v water pump selection, which is directly related to the pumping performance of the whole 12v water pump application system. Therefore, when selecting the 12v water pump, it should be based on the maximum flow and consider the normal flow. When there is no maximum flow, usually 1.1 times the normal flow can be taken as the maximum flow of the 12v water pump.

3. 12v water pump working environment.

If the environment in which the 12v water pump is used requires diving, such as in smart toilet, the 12v water pump that can be used as a submersible pump must be selected. If the ambient temperature and working fluid temperature you need to use are very high, such as solar water heater, automobile engine heat dissipation, electric vehicle battery heat dissipation and other high water temperature environments, you must select a 12V water pump that can withstand high temperature. For example, 12v water pump with a maximum operating temperature of 100 ℃ shall be selected for the solar water heater, and an electric water pump with a maximum operating temperature of 180 ℃ shall be selected for the fuel cell cooling system of new energy vehicles.

4. 12v water pump size and shape of water inlet and outlet.

When you choose 12v water pumpfor electrical appliances, equipment or water circulation system, you should choose 12v watr pump with appropriate external size. Therefore, it can be installed in the space of your design and left for the 12v water pump. If the remaining space of the 12v water pump is very compact, we recommend that you choose a 12v water pump with higher efficiency and smaller volume instead of other 12v water pumps with the same working performance. The direction and shape of the 12v water pump inlet and outlet should also be suitable for your piping system direction and joint type. For example, the inlet and outlet directions of 12v water pumps used on water heaters are usually in-line and threaded. In this case, you should choose a 12v water pump with 1/2 "or 3/4" threaded inlet and outlet.

5. Check product quality and reliability

Choosing high-quality water pumps can ensure better performance and service life. Check the quality standards, materials, and manufacturing processes of the product to ensure that the water pump you have chosen is reliable.

6. Consider installation and maintenance requirements

Installing and maintaining a 12V water pump requires certain skills and experience. Ensure that you understand the installation and maintenance requirements, and have the corresponding skills and experience to ensure the normal operation and service life of the water pump.

Characteristics of 12v water pump

1. 12V water pump generally refers to 12V DC power supply. Switching DC regulated power supply can be used for variable voltage power supply, vehicle battery can also be connected for power supply, and solar panel can also be used for power supply, which is very convenient to use. Compared with the AC water pump, it has a wider range of use and is safer.

2. compared with 24V water pump or 48V water pump, 12V water pump is quieter and has lower power. 12 volt water pump for garden hose

3. compared with the AC water pump, the 12v water pump is more safe, with exquisite workmanship, small volume, light weight, stable performance and convenient installation.

4. Small size, easy to carry. The 12V water pump has a small size and is easy to carry, making it easy to move to any desired location. This feature makes the 12V water pump an ideal choice for outdoor camping, emergency rescue, and other occasions.

5. Large flow rate and high lift. The 12V water pump has a high head and large flow rate, which can meet the needs of various occasions. Whether it's household water, farmland irrigation, or industrial production, the 12V water pump can provide a stable and efficient water source.

6. Low noise and stable operation. The 12V water pump adopts advanced noise reduction technology, which can maintain a low noise level during operation, bringing you a more comfortable living experience. Meanwhile, due to its stable operation, it also reduces the frequency and cost of maintenance.

7. Affordable: Due to its simple design and wide range of applications, 12V pumps are usually more cost-effective than some large AC pumps.

8. Portability: Due to the use of a DC power source, 12V water pumps can be easily connected to vehicle batteries or other portable power sources, making them more convenient to use outdoors, outdoors, or away from the power grid.

9. Multi functional use: The 12V water pump can be used in various applications, including but not limited to vehicle cooling systems.

10. Simple control: Due to the use of a DC power supply, controlling and operating a 12V water pump is relatively simple and can be controlled through switches or regulators.

11. Efficient and energy-saving: 12 water pumps are usually designed for high energy consumption to maximize the conversion of input electrical energy into water flow energy, thereby improving energy efficiency.

It should be noted that different types of 12V water pumps may have different characteristics, which may vary depending on the manufacturer and usage.

Installation mode of 12v water pump

1. Install the 12v water pump upwards.

2. The 12v water pump is installed horizontally and the water outlet is upward or horizontal.

3. It is not recommended to install the 12v water pump downward or the water outlet downward.

12v water pump fault and maintenance

1. 12v water pump Cause analysis and solution of liquid leakage.

1) Cause analysis: The screws of the 12v water pump were not tightened

Solution: Tighten the screws.

2) Cause analysis: The sealing ring of the 12v water pump is missing

Solution: fill the sealing ring

3) Cause analysis: There are impurities on the sealing ring of the 12v water pump

Solution: open and clean

2. High current, low flow

Cause analysis: There are impurities in the rotor of the 12v water pump

Solution: inject water from the water outlet to clean

3. No rotation, current is high and low

Cause analysis: The 12v water pump rotor is stuck due to foreign objects

Solution: eliminate the foreign matters that cause the rotor to be stuck

4. No rotation, short circuit current occurs

Cause analysis: 12v water pump control board damaged

Solution: Replace the control board

5. No rotation, no current

Cause analysis: The 12v water pump power line is not connected correctly

Solution: check whether the connector is connected well

6. Analysis and Solution of the Causes of High Noise in 12V Water Pump

1) Cause analysis: impurities in the 12v water pump

Solution: eliminate impurities

2) Cause analysis: there is gas in the 12v water pump that cannot be discharged

Solution: Place the water outlet upwards to ensure that there is no air in the liquid source

3) Cause analysis: there is no liquid in 12v water pump, and the 12v water pump is dry

Solution: Make sure there is liquid in the 12v water pump

Precautions for use of 12v water pump

1. 12v water pumps are prohibited from using liquids with impurities and magnetic particles greater than 0.35mm

2. When the 12v water pump is not in use for a long time, it is best to confirm that there is liquid inside the pump before powering on

3. Do not use the 12V water pump for a long time without liquid

4. When the 12V water pump is not in use for a long time, it is necessary to prevent dust from entering the inlet and outlet

5. Do not completely use the 12V water pump in liquids

6. Please confirm if the connection is correct before starting the 12V water pump, otherwise it may cause a malfunction

7. When using a 12V water pump in a low-temperature environment, please ensure that the liquid used does not freeze or become very viscous

8. If there are water stains at the wire joints of the 12V water pump, please clean the water stains before use

The difference between 12V water pump and 24V water pump

1. The voltage is different, one 24V and one 12V, both are very safe. The working voltage of a 12V water pump is 12V, while the working voltage of a 24V water pump is 24V. Therefore, when selecting a water pump, it is necessary to choose the appropriate working voltage type based on actual needs and power supply conditions.

2. Due to differences in voltage, the power of 12V and 24V water pumps may also vary. Generally speaking, the power of a 24V water pump is higher than that of a 12V water pump. Therefore, when it is necessary to deliver a larger flow rate or higher head, a 24V water pump can be chosen.

3. At the same power, high voltage and current are smaller, while low voltage and current are larger. A typical battery is 12V, but if 24V is used, two batteries are required.

4. The usage environment of 12V water pumps and 24V water pumps may also vary. Due to the low voltage of the 12V water pump, its heat generation is also relatively small, making it suitable for places with high environmental temperature requirements. The voltage of the 24V water pump is relatively high, and its heat generation is also relatively high. Therefore, it is necessary to pay more attention to heat dissipation issues to avoid equipment damage caused by overheating.

In summary, there are certain differences between 12V water pumps and 24V water pumps in terms of voltage, power, usage environment, and maintenance. In the process of selection and use, it is necessary to choose and use according to actual needs and conditions.

Advantages of 12V water pump:

1. Compared to AC electric water pumps, 12V water pumps are safer. The 12V water pump has a simple structure and is easy to maintain. The volume of a 12V water pump is usually smaller than that of an AC water pump, which makes it more suitable for use in environments with limited space. The 12V water pump has lower noise. In summary, compared with AC water pumps, 12V water pumps have advantages such as high efficiency, simple maintenance, small size, low noise, and energy conservation and environmental protection.

2. Compared with large water pumps, the 12V water pump has a compact structure and is easy to carry. A 12V water pump only requires a 12V power supply, while large water pumps may require higher power supply voltage or current. The operating noise of a 12V water pump is usually lower than that of a large water pump. The maintenance and repair of a 12V water pump is usually easier than that of a large water pump. In summary, 12V water pumps have many advantages compared to large water pumps, including lower power requirements, smaller volume and weight, lower operating noise, easier maintenance and repair, and a wider range of applications. Therefore, when choosing a water pump, it is necessary to choose the appropriate pump type based on specific needs and applications.

3. Compared to 24V, 36V, and 48V water pumps, 12V water pumps have a wider range of applications. The voltage of the 12V water pump is relatively low, so its energy consumption is also relatively low. Due to the lower voltage of the 12V water pump, its operating current is also relatively small. This makes the 12V water pump more stable during operation. The structure of the 12V water pump is relatively simple, so its maintenance is also more convenient.

Application scenarios of 12V water pump:

1. Automotive industry: In the automotive industry, 12V water pumps are mainly used to cool key components such as engines and transmissions. They transfer the heat generated by the engine to the radiator by circulating the coolant, thereby maintaining the normal operating temperature of the engine.

2. Household appliances: In the field of household appliances, 12V water pumps are mainly used for refrigeration and heating equipment, such as air conditioners, refrigerators, water heaters, etc. They play a crucial role in transporting cold and warm water, boosting water injection, and ensuring the normal operation and efficient performance of these devices. The stability and reliability of 12V water pumps have a significant impact on the performance and service life of household appliances, and therefore play an indispensable role in the manufacturing of household appliances.

3. Fire rescue: In the field of fire rescue, a 12V water pump can be used to extract water sources and provide firefighting water for firefighting equipment. These water pumps typically have a high flow rate and head to ensure that firefighting water can quickly reach the fire source and effectively extinguish the fire.

4. Domestic water use. Household water is one of the important application fields of 12V water pumps. In rural or urban areas where there is no running water, a 12V water pump can easily introduce groundwater or river water into the home, providing clean drinking water for family members. Meanwhile, in the absence of elevators in cities, a 12V water pump can also help residents introduce tap water into high-rise residential areas.

5. Irrigation of farmland. Farmland irrigation is another important application field of 12V water pumps. In rural areas, farmland irrigation requires a large amount of water source. By using a 12V water pump, river water or groundwater can be introduced into farmland, providing sufficient water and nutrients for crops. Meanwhile, due to the high head and large flow rate of the 12V water pump, it can also achieve remote irrigation and precision irrigation.

6. Industrial production. In industrial production, 12V water pumps also have broad application prospects. For example, in places such as chemical plants and pharmaceutical factories, a large amount of water is needed to cool and clean equipment. The use of a 12V water pump can provide stable and efficient water sources, while also achieving remote and automated control. In addition, a large amount of water source is also needed in construction sites to maintain construction progress and clean the construction site. The use of 12V water pumps can provide water sources more conveniently and quickly.

The Application of 12V Water Pump in Chillers

The function of 12v water pump is mainly to circulate the liquid cooled inside the water chiller to other equipment that needs cooling, and then take the liquid with high temperature to the water tank for cooling. In this way, the continuous circulation and exchange of cooling can achieve equipment cooling. The application of 12v water pump in the water chiller is simply a circulation function. The application of Shenpeng 12V water pump in the chiller industry includes P6005 chiller circulating pump and P4504 chiller circulating pump.

The Application of 12V Water Pump in Water Heater

The 12V water pump is usually the most common in zero cold water heaters, because every time the water heater is turned on, the water heater needs to heat the cold water first, requiring a long waiting time of several minutes to tens of minutes. Many users cannot bear this waiting time. Zero cold water heaters solve this pain point through the working principle of the 12V water pump, and do not need to wait, just turn on and use. The working principle of a 12V water pump is to circulate hot water to other places where water is needed, and to maintain the temperature of the hot water area at all times to achieve the purpose of instant use.

1. Using brushless motors increases efficiency by 30% compared to AC motors, and also ensures safe electricity usage.

2. Built in intelligent chip, which can adjust the flow rate and signal feedback according to the needs of the shower water temperature.

3. The 12V/24V/36V DC voltage is matched with the built-in power supply of the water heater, which can achieve stable voltage and current without being affected by peak electricity consumption, and ensure water output and water pressure.

4. Under the same parameters, compared to AC water pumps, the noise is lower and the shower enjoyment is better.

5. Smaller size and a long lifespan of 20000 hours, improving the design space and quality reliability of the water heater.

What is the maximum pressure of the 12V high-pressure water pump?

The maximum pressure of a 12V high-pressure water pump depends on its design, size, and flow rate. Generally speaking, the nominal pressure of a 12V high-pressure water pump is generally between 20-100 bar (200-1000 Kpa), but it can actually exceed 200 bar (2000 Kpa), depending on the pump design and construction.

The 12V high-pressure water pump consists of an electric motor and a specially designed pump, and the pump design determines the pressure range of the pump. The maximum pressure of a 12V high-pressure water pump depends on the design of the pump's casing and internal components. Generally speaking, when using pumps with higher pressures, the casing and internal parts of the pump are designed to be more sturdy than pumps with lower pressures, in order to withstand higher pressures. In addition, the construction of the pump casing and internal components can also affect the maximum pressure of the pump, such as its volume and flow rate.

It is worth noting that when using a 12V high-pressure water pump, its output pressure should be adjusted according to the specific application scenario. If the output pressure is too high, it may cause damage to pipelines and equipment. If the output pressure is too low, it may affect its work efficiency. Therefore, when using a 12V high-pressure water pump, appropriate adjustments and controls should be made as needed to ensure its normal operation and achieve optimal performance.

In summary, the maximum pressure of a 12V high-pressure water pump depends on the pump design, size, and flow rate, which can be adjusted according to the pump design and actual needs, but generally does not exceed 200 bar (2000Kpa).

What is a 12V diaphragm pump?

The 12V diaphragm pump has small volume, low noise, high pressure, and good self priming performance; Allow for dry operation, equipped with a pressure switch to protect the pump from damage during operation; The built-in overflow valve controls the normal operation of the pump, making it easy to disassemble and assemble. It adopts a safe low voltage to ensure personal safety.

Application field of 12v diaphragm pump: 12v diaphragm pump is committed to domestic tap water pressurization, automobile washing, ship and Shanghai water desalination, reverse osmosis water purifier, water treatment equipment, filter, spray device, chemical metering and liquid feeding, sanitation, environmental protection, printing and other industries

12V diaphragm pump product usage characteristics:

1. During installation, it is necessary to pull out the sealing caps at the inlet and outlet of the diaphragm pump.

2. Equipped with inlet and outlet connectors included with the pump.

3. The pump should be installed horizontally. If vertical installation is required, the pump head should be facing downwards.

4. Install a filter in the inlet and outlet pipes of the pump to ensure effective use of the pump.

5. The pump base is divided into nylon base and iron base rubber foot post.

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117