The best brushless DC pump:A Comprehensive Guide

Brushless DC pump is a machine that uses DC 4.5V, 6V, 12V, 24V, 36V, 48V to drive the brushless motor to operate. The brushless motor rotates to drive the impeller to increase liquid pressure and transport liquid. He has advantages such as efficiency, reliability, and durability. Brushless water pumps are mainly composed of brushless DC motors, impellers, pump bodies, shafts, and end caps. They adopt electronic commutation and do not require the replacement of carbon brushes. They have a long service life, small size, light weight, and simple maintenance.

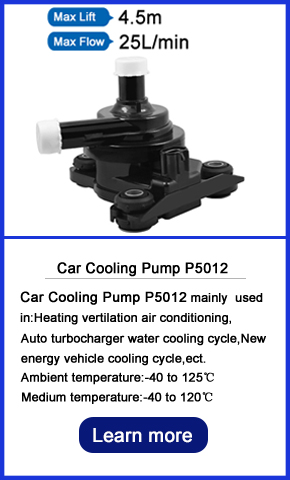

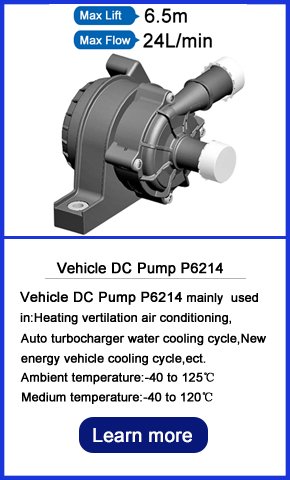

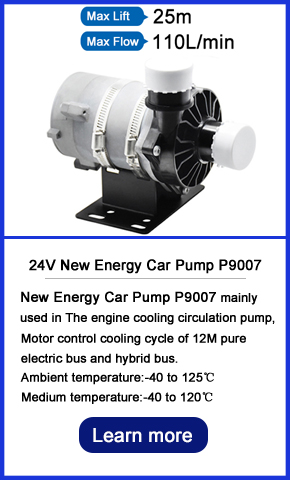

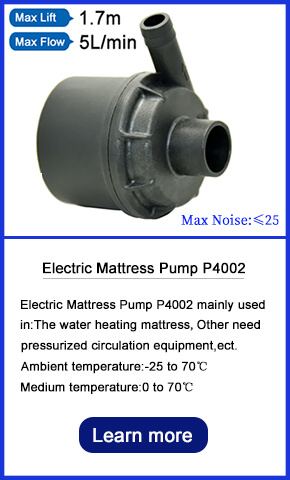

All Brushless DC pump by SHENPENG with lower price you will find here:

|  | |

|  | |

|  |  |

1.What is a brushless DC pump? 2. How to choose a brushless DC pump? 3. How does a brushless DC pump work and what is its working principle? 4. What are the applications of brushless DC water pumps? 5. Precautions for using brushless DC water pump? 6. What are the protective measures for brushless DC pumps? 7. Case study on selection of brushless DC pump 8. What is the difference between a brushless pump and a brushed pump? 9. Which is better, AC pump or DC pump? 10. Is the submersible pump brushless? 11. What are the common faults of brushless DC pumps and how to repair them? |

1. What is a brushless DC pump?

A brushless DC pump (Brushless DC Pump) is a type of pump equipment driven by a brushless DC motor. Its main components include a brushless DC motor, an impeller, a pump body, a controller, etc. The brushless DC motor replaces the traditional brushed motor, eliminating the friction and electric sparks between the carbon brushes and the commutator, and thus has higher efficiency and a longer service life. The impeller is responsible for converting the mechanical energy of the motor into the kinetic energy of the liquid to achieve liquid transportation. The pump body provides a flow passage for the liquid and ensures the tightness of the transportation process. The controller is used to adjust the rotational speed and operating state of the motor to achieve precise control of the pump.

The characteristics of brushless DC pumps are very remarkable. Firstly, they are energy - efficient. Since the brushless motor reduces energy losses, the pump can complete its work with lower energy consumption during operation. Secondly, they operate with low noise. The smooth operation of the brushless motor and the reduction of noise generated by brush friction give them obvious advantages in environments with high noise requirements. Thirdly, they have a long service life. Avoiding the failure risks caused by brush wear greatly improves the reliability and stability of the equipment. In addition, brushless DC pumps have good speed - regulating performance. The flow rate and pressure of the pump can be easily adjusted through the controller to meet the needs of different working conditions.

2. How to choose a brushless DC pump?

When selecting a brushless DC pump, multiple factors need to be comprehensively considered. First, the flow rate and head requirements. According to the actual usage scenario, determine the required liquid flow rate and the height that can be lifted to ensure that the pump can meet the actual transportation needs. Second, the working environment, such as factors like temperature, humidity, and corrosiveness. It is necessary to select the pump body material and sealing method that can adapt to the corresponding environmental conditions. Third, the power supply conditions. Brushless DC pumps require a DC power supply, and it is necessary to ensure the stability and compatibility of the power supply. In addition, factors such as the size, weight, and price of the pump also need to be considered.

The advantages of brushless DC pumps are obvious. Compared with traditional brushed pumps, they do not require regular brush replacement, reducing maintenance costs and downtime. Their energy - efficient characteristics not only help to reduce long - term operating costs but also meet the requirements of environmental protection and sustainable development. Their good speed - regulating performance enables them to accurately control the flow rate and pressure under different working conditions, improving the overall performance and stability of the system. Moreover, due to their low operating noise, they are suitable for noise - sensitive places, such as medical equipment, household appliances, and other fields.

3. How does a brushless DC pump work and what is its working principle?

The operation of a brushless DC pump is based on the principle of electromagnetic induction and the theory of the rotating magnetic field of the motor. Inside the brushless DC motor, there is a fixed magnetic field formed by permanent magnets. The controller periodically changes the current direction in the motor windings through an electronic commutation circuit according to the position of the motor rotor, thereby generating a rotating magnetic field. This rotating magnetic field interacts with the magnetic field of the permanent magnet to generate an electromagnetic torque, driving the motor rotor to rotate. The impeller is connected to the motor rotor. As the rotor rotates, the blades on the impeller push the liquid, causing the liquid to obtain centrifugal force and be thrown from the center of the impeller to the edge, thus achieving liquid transportation. During this process, the controller accurately controls the commutation time and magnitude of the current by detecting the position signal of the motor rotor to ensure the efficient and stable operation of the motor.

4. What are the applications of brushless DC water pumps?

Brushless DC pumps have a wide range of application fields. In medical equipment, such as hemodialysis machines, infusion pumps, etc., the pumps are required to have high precision, low noise, and high reliability. Brushless DC pumps precisely meet these requirements and can accurately control the liquid delivery volume to ensure the safety and effectiveness of the medical process. In household appliances, such as dishwashers, washing machines, water heaters, etc., the energy - efficient and low - noise characteristics of brushless DC pumps make them an ideal choice, enhancing the usage experience and performance of household appliances. In the industrial field, brushless DC pumps are commonly used in cooling systems, lubrication systems, and some production lines that require precise fluid control, such as the coolant circulation in the manufacturing process of electronic chips and the lubricant delivery of mechanical equipment. In addition, in the automotive industry, brushless DC pumps are also applied in automotive cooling systems, fuel injection systems, etc., improving the performance and reliability of automobiles.

5. Precautions for using brushless DC water pump?

When using a brushless DC pump, first, ensure correct installation. According to the requirements of the product manual, correctly connect the inlet and outlet pipelines, ensure good pipeline sealing, and avoid water leakage. At the same time, pay attention to the installation position of the pump. Try to choose an environment with good ventilation, dryness, and no corrosive gases to extend the service life of the pump. Before starting the pump, check whether the power supply voltage meets the requirements and whether the rotation direction of the motor is correct. During operation, closely monitor the operating status of the pump, such as parameters like flow rate, pressure, and temperature. Once any abnormality is found, stop the machine immediately for inspection. In addition, regularly maintain the pump, clean the surface of the pump body and the inlet and outlet, check the wear of the impeller and sealing parts, and replace the damaged parts in a timely manner.

6. What are the protective measures for brushless DC pumps?

To ensure the safe and stable operation of brushless DC pumps, a series of protection measures need to be taken. In terms of electrical protection, over - current protection, over - voltage protection, and under - voltage protection are usually set. When the motor current exceeds the rated value, the over - current protection device will automatically cut off the power supply to prevent the motor from being damaged due to overheating. Over - voltage and under - voltage protection can protect the motor and the controller from damage when the power supply voltage is abnormal. In terms of mechanical protection, an overload protection device will be installed. When the load of the pump is too high, the overload protection device will act to avoid damage to the motor and the pump body due to overload. In addition, temperature protection will be set. When the temperature of the pump body or the motor is too high, it will automatically stop running to prevent the equipment from malfunctioning due to overheating. At the same time, in the system design, a filter will be considered for installation to prevent impurities from entering the pump body and damaging the impeller and sealing parts.

7. Case study on selection of brushless DC pump

Suppose an electronic chip manufacturing enterprise needs to select a pump for its chip cooling system. The system requires the pump to provide a stable coolant flow rate in the range of 5 - 10 L/min, a head of 10 - 15 m, a working environment temperature between 20 - 40 °C, and a low - noise operation to ensure a quiet production workshop environment. After researching and analyzing various pumps on the market, a brushless DC pump was finally selected. The flow rate and head of this pump can meet the needs of the cooling system, and the low - noise characteristics of its brushless motor also meet the requirements of the workshop environment. At the same time, the pump uses corrosion - resistant pump body materials and sealing materials, which can adapt to the chemical properties of the coolant. In practical applications, the rotational speed of the pump is precisely adjusted through the controller to achieve stable control of the coolant flow rate, effectively ensuring the cooling effect of the chips and improving production efficiency and product quality.

8. What is the difference between a brushless pump and a brushed pump?

The main difference between brushless pumps and brushed pumps lies in the motor part. Brushed pumps use brushed DC motors, which have carbon brushes and commutators inside. During the operation of the motor, there is mechanical friction between the carbon brushes and the commutator, which will generate electric sparks. This not only increases energy losses and reduces motor efficiency but also causes the carbon brushes to gradually wear out, requiring regular replacement of the carbon brushes, increasing maintenance costs and downtime. Moreover, the electric sparks generated by the carbon brushes may also cause electromagnetic interference to the surrounding electronic devices.

Brushless pumps use brushless DC motors and achieve motor commutation through an electronic commutation circuit, eliminating the friction and electric sparks between the carbon brushes and the commutator. This makes brushless pumps have higher efficiency, a longer service life, lower noise, and better speed - regulating performance. At the same time, due to the absence of brush wear and electric spark interference problems, brushless pumps have obvious advantages in environments with high environmental requirements, such as medical equipment, electronic equipment manufacturing, and other fields.

9. Which is better, AC pump or DC pump?

AC pumps and DC pumps each have their characteristics. AC pumps usually have a simple structure and a lower cost, and are suitable for some cost - sensitive occasions with low requirements for control accuracy, such as ordinary industrial drainage, agricultural irrigation, etc. They can work directly when connected to an AC power supply without the need for complex power conversion devices. However, the speed - regulating performance of AC pumps is relatively poor. Generally, speed regulation can only be achieved by changing the number of pole pairs of the motor or using a frequency converter, which is costly and complex to control.

DC pumps, especially brushless DC pumps, have advantages such as high energy efficiency, good speed - regulating performance, and low noise. They are powered by a DC power supply and can achieve precise speed - regulating control with the cooperation of a controller, and can flexibly adjust the flow rate and pressure according to actual needs. However, DC pumps need to be equipped with a suitable DC power supply and controller, and the overall cost is relatively high. In some occasions with high performance requirements and the need for precise control of flow rate and pressure, such as medical equipment, high - end household appliances, etc., DC pumps have more advantages.

10. Is the submersible pump brushless?

Submersible pumps can be either brushed or brushless. Traditional submersible pumps mostly use brushed motors, which have a relatively simple structure but have problems such as brush wear, low efficiency, and high noise. With the development of technology, brushless DC submersible pumps are gradually being applied. Brushless DC submersible pumps have many advantages of brushless motors, such as high energy efficiency, low noise, and a long service life. In some diving application scenarios with high performance requirements, such as deep - well water extraction, underwater aquaculture aeration, etc., brushless DC submersible pumps can better meet the needs. They can operate stably underwater for a long time, reducing the frequency and difficulty of maintenance and improving the reliability and use efficiency of the equipment.

11. What are the common faults of brushless DC pumps and how to repair them?

The common faults of brushless DC pumps mainly include motor faults, impeller faults, and sealing faults. Motor faults may be manifested as the motor not rotating, abnormal rotational speed, or overheating. The motor not rotating may be caused by power supply faults, controller faults, or short - circuit or open - circuit of the motor windings. At this time, it is necessary to check whether the power supply connection is normal, measure whether the power supply voltage meets the requirements, check whether the controller is working properly, and use professional tools to detect the resistance value of the motor windings to determine whether there is a short - circuit or open - circuit situation, and repair or replace the corresponding components according to the specific problems.

Impeller faults usually manifest as impeller wear, breakage, or being stuck by foreign objects. Impeller wear or breakage will lead to a decrease in the pump's flow rate and head, and at this time, a new impeller needs to be replaced. If the impeller is stuck by foreign objects, stop the machine and clean the foreign objects to ensure that the impeller can rotate freely.

Sealing faults are mainly manifested as water leakage. It may be caused by the aging, damage, or improper installation of the sealing parts. For the situation of aging or damage of the sealing parts, new sealing parts need to be replaced. If it is due to improper installation, the sealing parts should be reinstalled correctly to ensure good sealing. During the repair process, it is necessary to strictly follow the operating procedures to ensure the repair quality and restore the normal operation of the pump.

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117